How to make an effective juicer for processing apples

Is it possible to achieve an output of 65-70 percent of apple juice from the processed mass? Can. Only we need to count not on the strength of the press created in the juicer with the help of a jack, but pay attention to the preparation of the raw material and the way it is pressed. The best raw material is apple crumb size 3-4 mm, not larger.

And completely unacceptable is gruel, from which it is practically impossible to wring the juice: it either leaves the skin or clogs the filter.

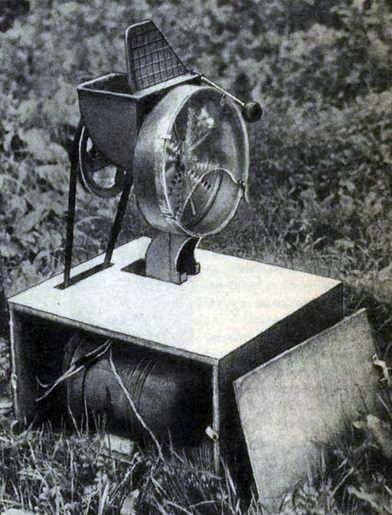

For more than 15 years, the pulp of the desired consistency (in the form of crumbs 3-4 mm) from apples or the crushed berries of currants, mountain ash, etc., except for cherries – bones interfere), I cook on shredding, which was mechanized.

In order not to peel apples from the core (mainly from seeds) and pedicels, which, when crushed, impair the quality of the juice, it is necessary to withstand a certain number of rotations of the disc at which the pulp is ground, and the seeds and pedicles remain intact and do not interfere with the squeezing of the juice.

The number of revolutions of the disc (graters) should not exceed 300 per minute and be not less than 80 – otherwise the grater will be clogged with a skin of apples. When reconstructing the shredder, I used a cone-shaped pulley and belt from the washing machine. The electric motor is 170 watts and 1200 rpm.

The leading pulley was made by itself. To do this, on the shaft of the engine secured a blank from the textolite (it can be made of solid wood: apple, etc.) and already on the rotating shaft with a chisel and file turned a pulley of the right size under a wedge-shaped belt.

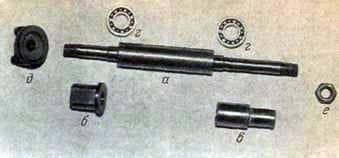

The platen on which the disc (grater) and the pulley are attached, made of stainless steel and put the roller on ball bearings, preferably also in stainless steel. The most suitable for this purpose were bearings No. 10 001 (inner diameter

Expanding the shredder hole from both ends to 20 mm to a depth equal to the thickness of the bearing, I fixed the bearings and set the roller:

A – the roller itself, the length of the middle part together with the bearings should not exceed the thickness of the wall of the shredder body; b – coupling on which the disk (grater) is fixed; c – a coupling for the pulley nozzle (both couplings have threaded holes for bolting on the shaft, so they will not be checked); З – bearings № 1000, it is better than mark “А”; d, e – nuts.

The performance of this shredder is 1 bucket of apples in 3-4 minutes. Load the hopper by 1 to 2 apples, pressing them with a flap to the disc. To the pulp does not scatter, on the front of the shredder put on a hemisphere of plexiglas. In the lower part – a hole for the exit of the pulp.

From the resulting pulp juice squeeze using a homemade screw press. For him, he used parts from the old water valve. The main effect of the press is achieved not due to the force of the screw, but by increasing the surface of the pressed mass. It is necessary that the juice can go not only in the upper part, but also from the bottom and from the sides and even inside the mass.

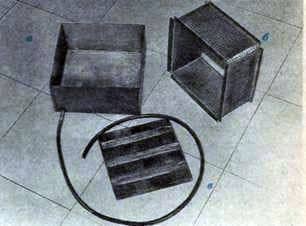

This is achieved by means of tanks, gaskets and linen: a – a top tank measuring 250 x 250 x 120 mm with an outlet at the bottom at the bottom of the hose; b – internal tank of 220X220X120 mm in size with lattice walls and bent outside boards to stiffen the walls and to keep the inner tank at an equal distance from the walls of the main tank; c – wooden spacers with the size of 215 x 215 x 6 mm (material – hard wood parquet with rounded rails filled on both sides).

To ensure that the gaskets are always dry and not colored in the color of the juice, especially when squeezing black currant or black ashberry, they must be made of dry material and dipped in molten paraffin, and even better – in beeswax. This coating has lasted for many years.

Loading of the pulp is as follows. On the table, chair or other place the tanks are assembled, the gasket is laid on the bottom (the second end of the hose is also removed to the corner of the tank so that the juice does not go away), the linen spreads, it is better from the coar coals: it is durable, much denser than cheesecloth, 50×60 cm. the canvas is filled up to 2 liters of mash: it no longer follows, since it is difficult to squeeze out from the inside. The mash from above is closed by the ends of the canvas in the form of an envelope, a gasket is placed on the envelope. A packet is obtained between two gaskets. Then again, the envelope and again the gasket.

And as many packages as the tank height allows. I’m preparing 3 packages, the last one at 12-15 cm rises above the tank – this is permissible, since with the pressure all the mass will go into the tank.

The last package is also closed with a gasket, it is put on a plate of the same size of solid wood, on it – a support bearing or a solid washer, which will rest on the screw. At the slightest pressure, the juice starts to come out of the mass from all sides, and is collected through a hose into a prepared container.

Of the three packages with a total mass of 4.5-5 liters, I get up to 3 liters of pure juice. The amount of juice depends, of course, on the starting material: the varieties Renet Simirenko, Papirovka, Desert Petrova, Melba give juice more than Cinnamon striped, Autumn striped and overripe apples. The canvas performs two functions in work: it filters the juice and facilitates the extraction of pulp.

The resulting juice is heated in a tank to a temperature of 76 њ (the tank is equipped with a special valve, where a thermometer is inserted). Then I pour into sterilized jars and close them. It is stored for years in room conditions.

How to make an effective juicer for processing apples