Apiary equipment and equipment

Portable multi-operation stand

The use of typical machine tools, which has significant dimensions and cost, not every apiary is available.

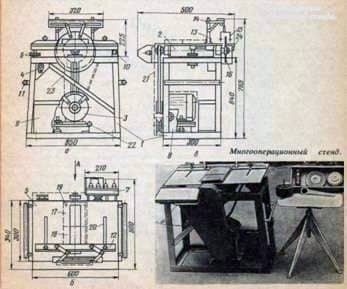

To facilitate carpentry, a portable small-sized stand design has been developed, which can be moved and installed in any convenient place. It is adapted for sawing and planing wood, selecting quarters in boards, drilling holes, sharpening tools, drilling holes in a wire under a four-spindle head, polishing surfaces, cleaning the ceiling frames of hives from propolis.

The stand consists of a frame 1, welded from a steel corner. On the frame in the housings on ball bearings a shaft of operating elements 2 is installed, rotated by a belt drive from a single-phase electric motor 3 with a power of 0.6 kW that is connected to a 220-volt power switch with a button switch 4. The table of the stand 5 is made of a steel plate and can be adjusted in height relative to of the knife shaft 2 by means of a screw pair 6, which facilitates adjustment to a certain depth of cutting (planing).

The shaft of working elements consists of a knife head, a seat for fixing a circular saw, an abrasive wheel, a felt wheel, a drill chuck, and a belt pulley. For drilling holes in the hive framework under the wire on the upper base of the frame, a four-spindle head 7 is installed.

To use the electric motor of the stand as a drive for the honey extractor when pumping honey on the bottom base, a reducing gear 8 is installed, which allows reducing the speed transferred to the drive of the honey extractor to 60 rpm.

Work stand. To saw the wood on the seat of the shaft of the working organs, the saw blade should be mounted and fixed, and the adjusting screw pair adjust the position of the table (depending on the depth of the cut) so that the saw’s outreach above the table is not more than 40 mm.

The worker turns on the electric motor and gently feeds

For planing, it is necessary to first adjust the table in height, depending on the cutting depth, so that the blade knife of the cutting edge rises above the table plane by a given depth.

To select quarters on the boards, the table is positioned so that the saw blade rises above its plane to a height equal to the depth of the quarter, then the guide square is set at a distance from the circular saw equal to the width of the board to the quarter cut.

To drill holes, you must first remove the saw blade from the shaft of the working parts, then screw the chuck to fix the drill to the threaded end of the shaft, select and fix the required drill in the chuck, turn on the electric motor and feed the workpiece smoothly to the rotating table.

To sharpen the tools, it is necessary to install and fix the abrasive wheel and the safety guard on the threaded end of the shaft. When sharpening the tool, use a sliding square 24 as a tool.

To drill holes in the framework of a wire, it is necessary to remove the belt from the pulley of the working parts and to reposition it on the four-spindle head pulley, turn on the electric motor and, placing the frame with a side bar on the drilling platform support pad, smoothly feed it to the rotating drills until the drill is completely through, then remove the frame, turn it 180 њ and drill the holes in the second side bar.

To polish metal surfaces, it is necessary to install and fix a felt wheel on the threaded end of the shaft, apply a paste “GOI” on its surface or another used for this purpose, turn on the machine and, smoothly pressing the part to the rotating wheel, polish.

For cleaning metal or wooden products from rust, putty, paint, propolis, etc., a cordolent is used, which is fixed on a wooden circle in a manner similar to the previous tools.

To use the electric drive of the stand as a Drive for the honey extractor when pumping honey, it is necessary to first remove the handle of the manual drive of the honey extractor and install the pulley of the belt transmission (available in the stand assembly) to the seat of the drive shaft, then remove the belt from the pulley of the stand’s operating elements and put it on the pulley of the lowering reducer 8, and on the driven pulley of the reducer, put on the belt, which transmits the rotation onto the pulley of the honey extractor.

The multi-operation stand and the honey extractor should be firmly secured after preparation for work.

The use of a multi-operation stand for labor-intensive work in the apiary significantly increases the productivity of the beekeeper.

Apiary equipment and equipment