How to make a tub

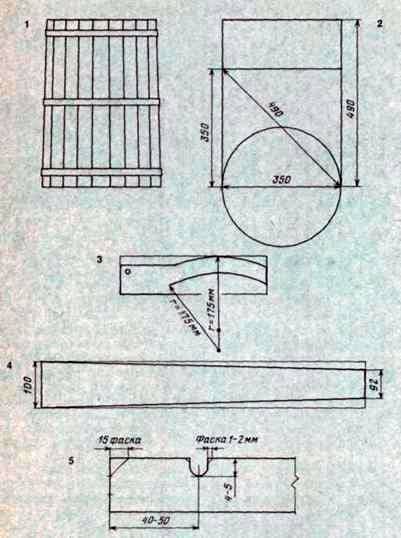

In the pictures:

1 – The tub, the general view;

2 – ratio of the diameter of the tub and its height;

3 – Template;

4 – Marking riveting;

5 – Fragment of riveting with cut out chipping (deepening) and bevelled chamfer on the bottom.

In the household, tubs are in great demand. They have ham in the brine, salt bacon, ferment cabbage, and soak the apples.

The tub is a wooden container with one bottom. The shape is a truncated cone. Making a tub is easier than a barrel. Make a tub for 3 hoops, it turns out solid and fine. They make a tub of separate plates – rivets, chipped out of chuk. Riveting of sawn timber is almost useless.

Preparation of riveting. For bonded products, the best wood will be oak, beech, maple and linden. You can make troughs made of alder, spruce, larch, pine and aspen. However, a tub made of coniferous wood must be thoroughly soaked in hot water, otherwise extracts and resins will inform the products not of their own smells and smack.

The sequence of blank riveting is as follows.

From the ridge of a tree as large as possible, we can cut off a chunk 1-2 cm longer than the height of the future tub. Then we remove the bark and put the chock vertically with the commomial part on a solid base. With the help of a mallet we can make an incision from the far and near side, then we place the point of the ax in the middle of the chock and split it in half. Then once again, split each half in half, placing an ax across the annual rings.

For the maximum yield of riveting, starting with a quarter of the stump, we shackle or chop off the side edges an acute angle directed toward the center of the segment, as a result, the quartet can be split into 2 or 4 parts. The annual riveting according to the thickness must be at least 20-25 mm. Of course, the number of suitable rivets depends mainly

Sort out the split riveting and proceed to her father-in-law with a hatchet. To make the tub turned comfortable and pleasant for the eye, the ratio of the diameter of its lower part and height should be in the proportion of 35:49. Increasing or decreasing the height, it is necessary to increase or decrease the diameter of the container. The volume of the tub is usually determined by the formula of the volume of the cylinder, since there is no need for more accurate counting at home.

The number of rivets on the frame of the tub is calculated by the formula: Д И 3.14: Ы , where д – diameter of the tub in the lower section; W – the width of the riveting at the bottom of the tub.

Riveting to the bottom is selected after determining the diameter of the bottom by the chops. For the bottom choose riveting on a wider, the last of them are called jambs, the middle ones are called teters.

Stretch the riveting with a planer, adjusting each in thickness; immediately determine which side will be external, strengthening the manifested feature and slightly zapolivalivaya left and right sides of the riveting along the length. Cherchebel with an oval point is scraped (according to the template), the inside is cleaned and a line is drawn with a pencil, dividing the riveting in half along the length. Then with a hacksaw with fine teeth, rivet the rivet along the length and take out the dividing line to the ends.

Fugankom do the outer and lateral sides of the rivet completely, checking the correctness of planing according to the template made according to the given parameter of the tub. Make a template taking into account the radius of the bottom hoop tub. Especially carefully check the correctness of the side jaws of the rivets. The template should be adjacent to the side and outer sides of the riveting without a gap. Do not allow deviation from the sides of the line on the end, dividing the riveting in half, when planing the lateral sides.

The layout of the riveting for the tub produces the following. Take a plate, previously ostrochennoy after otetki, with a width of 30 to 100 mm, is carried out along the outside of the line, dividing the riveting in half in width. To obtain the conicity of the tub, it is necessary to withstand the tapering of the rivet, it should be about 8 њ. This means that with a rivet width at the bottom of the tub 100 mm above it should be 8 mm already, that is 92 mm. Fix the established rivet width with dots and connect the four points with lines. These are the guidelines for planing riveting and will help get a taper.

Assembling the tub. We’ll make an assembly hoop, the middle between the top and bottom of the tub.

Then, on a clean wooden base, we put a vertically prepared hoop and put inside it 6 rivets with the outer side to the hoop. On the left, one of the rivets and the hoop will be clamped with a clamp. The rest of the riveting will also be put in place and lift the entire workpiece, we will tighten the hoop. The tight fit of the clasps to each other is the result of a careful cut and fit.

Now it remains to fill in the skeletons of the upper, middle and lower hoops. And as we fill them, we put the frame of the tub on the workbench and we process once again its inner surface completely. With a double planer and chisel we work the ends of the skeleton and cut the chamfer from the inner part of the lower end by 1/3 of the rivet thickness. We also fill the upper end of the tub. When performing these operations, use the appropriate tool.

Now it remains to put the bottom.

With a tool (tool), cut the groove depth and width 4-5 mm at a distance of 40-50 mm from the edge of the lower end. The chamfer is removed from both sides of the groove with a small chamfer (1 – 2 mm). On the bottom shield (it is collected on metal stiletto heels) to draw a circle. Luchkovaya saw with a blade is not wider than 7 mm and teeth for longitudinal sawing sawed to the bottom.

Put the bottom of the circle on the workbench, we clean it from both sides and at the end with a pencil in the middle we draw a line 2-3 mm thick. The radius is 25-30 mm smaller than the bottom, draw from two and the sides of the circle. These are the boundaries of chamfering. With a chisel and a planer, we remove the chamfers and make sure that the stub groove and the chamfered chamfers of the bottom approach each other.

The line along the butt of the Don remained untouched. We turn the frame of the tubs wide part up and lightly knock off the hoop. We put the bottom into the fixed groove and put the hoop back on its place. We make sure that the bottom is clamped with rivets in the chops and the rivets between them would not have gaps. At the final deposition of the hoops we will check the tub for verticality.

In conclusion – advice. Immediately after splitting the scallop on the riveting, proceed to processing the blanks, until the end of the tub making. With wet hardwood it is easier to work, especially if all operations are done manually.

Soak the oak barrel from the extracts for at least 10 days, every 2 days changing the water.

Do not forget to make two pairs of jambs, so-called circles for closing top-fermented vegetables. They put a load on them, usually a stone. The jambs are soaked and dried together with a tub.

Ogorodniku master the profession of Cooper quite good.

How to make a tub