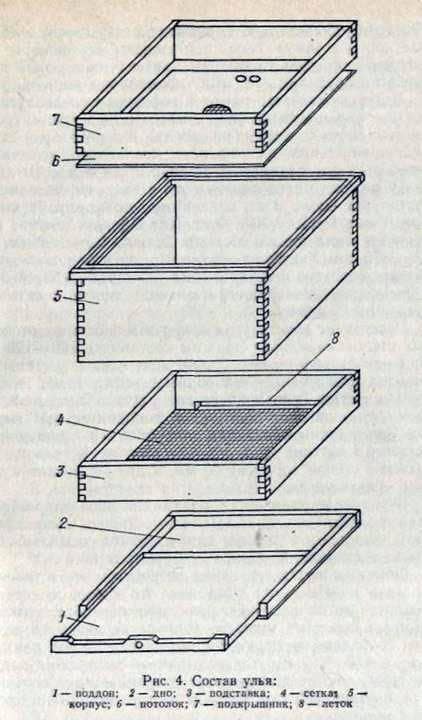

Device of the hive for the pavilion

It is now generally accepted that the vertical arrangement of the hives is more in keeping with the natural habitat of the bees – the hollow. The desire of bees to develop a nest in a vertical direction is well traced in multi-hull beehives. If such a hive contains more than 10 frames in one body, then if possible to develop a nest vertically, the bees do this, leaving a part of the honeycombs on one side of the shells free.

In different countries in a multi-hive beehive it is customary to have from 8 to 10 frames. Such hives allow you to exert the necessary effects on the life of the bee family for longer periods and with less labor because they are designed to work with whole bodies, rather than with separate frames.

Taking into account the content of bees in the pavilion and the possibility of additional warming of the hives, the thickness of the walls of the nest cases can be assumed to be 20-22 mm, which significantly reduces the mass of the hull.

Honey enclosures can be made from plywood or hard fibreboard with edging with wooden blocks – by the type of parcel boxes.

The choice of the number of frames in the body, and therefore its width and maximum mass, are determined by the physical capabilities of the beekeeper and, to some extent, rational placement of the desired number of hives near the pavilion wall.

The case is usually designed for 8-10 frames. The weight of one honeycomb with sealed honey is about 3 kg, therefore, the body with honey can have a mass of 30-40 kg. For 8 frames, the width of the enclosure without taking into account the wall thickness should be 300 mm, for 10 – 375 mm.

Taking into account some advantages of square cases with internal dimensions of 450×450 mm and physical capabilities of the beekeeper, it is possible to make cases on 12 frames.

The

So, at the wall of the pavilion with a length of 2.6 m, four hives with shells for 12 frames are normally placed, with a wall thickness of 20 mm, and with 10 frameworks – five hives.

In conditions of the reality of the bee’s disease varroatosis, beehives must necessarily be provided with a detachable bottom, a pallet with a mesh to isolate the mites and carry out medical measures.

Experienced, as well as studying the natural habitat of bee-hollows, it is proved that bees develop better in summer and are much easier to tolerate hibernation if under the frames of the lower hull to the bottom of the hive a free space is created not 20 mm high, as is customary, but 150-200 mm, so called air cushion. The necessary under-frame space is provided by placing under the lower casing of the stand of the required height.

In the spring, when you need to rearrange the buildings, bees do not build up a large podramochnoe space cells, because at this time they are mastering the warmest upper housing. At the last rearrangement of the buildings (in the beginning of June) there may already be tongues with drone honeycombs and brood on the lower framework, cutting off which increases the yield of wax and promotes the destruction of the tick.

In the summer and autumn periods, when the nest cases are not rearranged, in some families it is possible to build up the sub-frame space by several tongues of tartar honeycombs. This provides an increase in the volume of nest and reserves of honey for future use, improves wintering conditions.

At a spring inspection of families these honeycombs are empty and cut out or used for growing a tart brood.

The hive has a ceiling made of hard fiberboard or plywood, a 120-150 mm hood and a roof. Instead of a solid ceiling in spring and summer, you can use a canvas. The roof is needed most often during the feeding of bees in autumn, it closes the trough in the overburden. If you use feeders with their own roofs, preventing the flight of bees, then the hive can remain without a roof.

To limit the brood nest with the uterus or to remove the hull from the uterus from other hulls, a separation grid must be included in the hive kit. In addition, the composition of the hive includes a ceiling-diaphragm, a feeder with a dam, a moss warmth cushion, ventilation pipes (two on a hive) and a drinking bowl.

The bottom of the hive consists of three parts: the bottom itself, the pallet and the antivaratoat grid. The bottom can be plywood or solid wood fiberboard. It has on three sides a strap from wooden bars 25X60 mm, which is tightly fastened to the bottom on screws, nails and casein glue. The back of the bottom does not have a strap.

The internal dimensions of the bottom must correspond to the internal dimensions of the shells. Instead of the rear bar, a pallet bar is moved under the wall of the stand.

The pallet is made from a sheet of aluminum or an aluminum alloy 1-1.5 mm thick. Make a tray in the form of a pan according to the internal dimensions of the bottom. The edges of the pallet are beaded at a right angle of 15-20 mm, and from the rear side a bar like a bottom bar is attached to it, with dimensions that allow it to freely enter between the side bars of the bottom under the net and the back wall of the stand.

In the middle of the pallet block, a handle is attached (for ease of operation), and in the upper part, on both sides of the handle, cuts of 100-120 mm in length and 15 mm in height are cut to ensure ventilation of the hive (from the side of the pavilion) in winter.

It is not recommended to make pallets from thin metal sheets, they unnecessarily rustle during work, disturbing the peace of bees, which is especially harmful in winter, when pallets have to be removed for inspection.

The antivarotasis grid is made according to the external dimensions of the bottom and can be any: metal or plastic with cells or distances in the lumen from 2 to 3.2 mm. More practical than grids made of galvanized steel wire 0.5-0.8 mm in diameter, edged with strips of sheet aluminum. Grid (grate) is nailed to the bottom bars with small nails.

The stand is made of the same boards that go to the body. To extend the range of use of the stand, its height can be made the same with the overburden (130-140 mm). If in the overburden there are folds under the frame hangers, then it and the stand can be used as a hull or by a flap from below, if the stand is installed by the downward cutout, or in the middle of the hull after it has been installed upwards.

The last position can be used to create the layers. The pilot cut is made in the front wall of the stand, its height is 20 mm, but the edges should not extend to the side outer walls of the stand by 50-60 mm.

The shell of the hive for the pavilion, as already mentioned, is thin-walled (20-22 mm), and has a flameless structure, on the upper part of the anterior and posterior walls of the sample under the shoulders of the frames. In thin-walled casings for the convenience of gripping to the side walls at the top, you can nail (with gluing glue) racks of cross section 25 X 12 mm for the entire length of the case. In this case, hive bodies will always be placed perpendicular to the wall of the pavilion, that is, to a cold drift.

If the beekeeper wishes to put 12-frame hulls of his hives on a warm skid, that is, honeycombs located parallel to the wall of the pavilion, which is facilitated by their square shape, then it is necessary to nail the slats on all four walls. The internal dimensions of the case will be as follows: for 12 frames – 450 x 450 mm, for 10 – 450 X 375 mm and for 8 frames -450 X 300 mm.

Honey casing is better made from plywood or hard fiberboard, which goes to the parcel boxes. There are no upper tapholes in the hulls. If necessary, their role is played by the cutoff notches in the dividing ceilings – the diaphragms, which are completed with half of the hives.

In recent years, interest in beehives from expanded polystyrene (expanded polystyrene, polyurethane foam) has been increasing. But this material may not give the expected effect. After all, the body of pine boards with a thickness of 20 mm has a mass of about 5 kg, and a body made of expanded polystyrene with sufficient strength for operation (with a density of 150-200 kg / m3 with a wall thickness of 40 mm) – about 4 kg.

Styrofoam with a lower density will not be strong enough, and bees can gnaw it. Using such a case, we get a gain in mass of about 1 kg with a total mass (with frames and honey) of 30-40 kg. Yes, he will have more heat insulation. However, the lower thermal insulation of the wooden case is compensated by its additional external warming in cold weather and convenience of operation.

Polyfoam with a density of 12-18 kg / m3 makes sense to fill the gaps of double-walled street hives, which significantly reduces their weight and improves thermal insulation, without reducing other performance characteristics.

The pavilion hive is the same as the stand. As mentioned, it is possible to select folds under the frame hangers to be used together with the stand as a backup hull in the formation of layers. He does not have a cutout.

The ceiling of the hive must be solid (from plywood or fiberboard), solid. It makes two holes 25 mm in diameter (in the middle, at one of the walls of the body) for the passage of bees to the feeding troughs with top dressing and for ventilation in the winter. The same purpose is served by a hole in the center of the ceiling with a diameter of 85 mm, sealed with an insert, through which (if necessary) the bees are fed in winter and early spring.

In summer, you can use ceilings from the canvas. However, solid ceilings, when fastened on their underside or by laying one or two blocks of 8 mm thick, provide a guaranteed overframe space, which allows bees to freely enter the feeder, provides better ventilation and a more even distribution of acaricides in the beehive during bee treatment. Canvases, two on a hive, are used for family inspections.

A great advantage of hard (air and water vapor tight) winter ceilings is that the moisture removed from the hive through ventilation tubes does not get into the warming pillows, which, being on a warmer ceiling, are not moistened, but dry out more and better retain heat. It is no accident that the ceiling after wintering remains always clean. It seems that bees in winter in this way because of the lack of propolis eliminate the excessive permeability of the ceiling.

A moss cushion (insulating) with a thickness of 150-200 mm should fit tightly into the overburden. The pillow case is made of a dense, but breathable cotton or linen material, burlap can be used.

Device of the hive for the pavilion