How to cut foam

Good sound insulation properties are foam plastic OPBS-35, which is available.

When using it, it is convenient to cut through the thickness into two plates of 49.5 mm; three for 32.5 mm; on four and five plates accordingly on 24 and 19 mm. It is not difficult to do this with a simple device that every beekeeper can make.

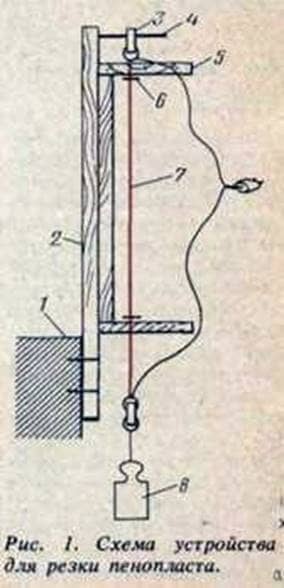

As a cutting tool, you need to take a nichrome thread 7 1 m long from an electric or iron. To the lower end, attach a weight of 8 to 1-3 kg. The size of the cargo should be selected practically, the thread should not sag and break off at random jerks or at the end of cutting. Mount it is necessary through the insulator 3, reinforced on the pin. The porcelain rollers or porcelain parts of the electric kettle plug can serve as an insulator. To make a vertical support platform, a chipboard or a plywood sheet with a thickness of 7-10 mm is taken. If they make it in the form of a lattice, then take four blocks, have it in parallel and under their ends on both sides are pounded on the bar.

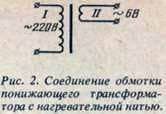

In relation to this site, the distance to the cutting wire is determined, which determines the thickness of the plates produced. Two boards 5 with width more than 100 mm are attached from below and from above to the supporting plane. Lower serves as a table, on which the foam is moved. In the boards for the thread from the side of the reference plane, the propyl is made. The device is fixed on a bar 1 with a thickness of 30-50 mm, which, in turn, is inserted into the vice. For greater accuracy, the cutting thread 7 in the cuts of the horizontal boards 5 is passed through the holes in the tin plates 6 nailed to these boards. Electric current for heating the nichrome wire can be obtained by connecting the secondary winding of the step-down transformer (voltage ~ 6 V) with the heating wire.

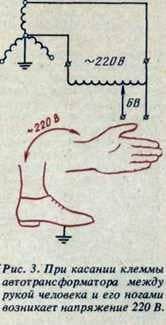

The autotransformer, as well

Therefore, if you accidentally touch a thread or a conductive path, a person will inevitably be under stress.

During operation, it must be ensured that the filament does not strongly heat up, as part of the foam burns out and the surface of the resulting plates becomes wavy. Promote the sheet smoothly, slowly. At the end of cutting, try not to jerk, as under the action of the load the thread stretches and you can cut it off.

The dimensions of the device must be such that when cutting a plate in height it can freely pass between the lower and upper guide boards with a margin of 5-7 cm. The length of the vertical support platform and the lower support board should be one and a half times larger than the foam. For high-quality polyfoam filling of wireframe products (hive from chipboard, double-layered plywood nomadic booth, etc.), I recommend to transfer dimensions to a sheet, easily tapping it “in place” on the edge of the carcass bars. According to the weak marks formed from the ribs of the bars, the sheet is cut with a knife on the rack, obtaining the desired shape and size.

How to cut foam