Hive

Currently, almost all bee colonies of Ukrainian apiaries are kept in so-called frame hives. In these hives each honeycomb is enclosed in a rectangular wooden frame, which can be freely removed and inserted back into the hive, and therefore in such hives it is easy and convenient to carry out work on the care of bees.

The frame hive was invented in 1814 by the most prominent Ukrainian beekeeper, the founder of rational beekeeping, PI Prokopovich in the village of. Mitchens in the Chernigov region. PI Prokopovich was an outstanding figure in Russian beekeeping and the founder of Russian beekeeping literature. In 1828, he founded the first folk school of beekeeping, which taught literacy and beekeeping. During the existence of the school, more than 500 people, mostly serfs, were trained in it; this undoubtedly had a positive effect on the improvement of the state of beekeeping in Russia.

Before the invention of the collapsible beehive, Prokopovich, bee colonies in Russia and elsewhere were kept in primitive hives, mostly in so-called duplexes and decks.

In order to get honey and wax from families in indiscriminate hives, beekeepers destroyed bee colonies at the end of the season, “lighting” them with sulfur, after which they broke out the honeycombs. Such a system of beekeeping was called “swarm” or, in the words of PI Prokopovich, “fighter”. In most cases, the best, more productive families were destroyed.

PI Prokopovich, inventing a framework hive, at the same time the first developed a method of bee-keeping, in which honey was selected without “lighting” bee colonies, thereby creating the basis for breeding the most productive bee colonies.

The Prokopovich hive was arranged as follows. It was made of boards and had a square section. Doniev was two: the upper and lower. One of the walls of the hive was made detachable and

The upper septum had slits of this size that through them the bees could pass, and the uterus – no. This is invented by Prokopovich, the dividing board with the passages for bees is a prototype of the “separation grid”, sometimes used on apiaries and now. It was in the upper section, the hive, that the frames invented by PI Prokopovich, in which the honeycombs were built up by bees, were filled with honey bees. The middle and lower compartments of the hive had no framework, but methods of keeping bees were used such that the nesting honeycombs were periodically updated.

In the future, the frame hive was subjected to various improvements, the size and shape of the frames, the design of the hive, etc. changed. The beekeepers of our country also played a significant role.

The distribution of frame hives was facilitated by other improvements in beekeeping, especially the invention of honey extractors and artificial honeycombs.

Requirements for the hive. A modern frame hive must meet many requirements. First of all, it should be a comfortable home for bees, spacious enough for the development of a strong family in it and the folding of fodder (nectar, honey, perga). The beehive must reliably protect the bee from adverse weather conditions: dampness, cold and heat. It should be provided with sufficient ventilation especially necessary for transporting bees, during the main bribe and during the wintering of bees.

The hive should not have too wide or too narrow aisles; they should be such that through them bees can pass freely, because the bees tend to build up wider and wider intervals with honeycombs, and all narrow, not able to serve as passages, are covered with bee glue (propolis).

All passages should be of a normal size – from 7.5 to 8 mm. Usually such passes of the bee do not build up and do not cover up.

If a beehive is placed on the hive to increase its volume, then between the upper bars of the frame of the body and the lower bars of the frame of the extension, there must also be a passage of 7-8 mm. With a wider passage, the bees can tie the frames of the body to the frame of the extension with waxen superstructures, which, when removing the superstructures, will collapse and honey will flow, which is highly undesirable. With a small amount of this passage, the beekeeper will press the bees during work. The distance between the mediastinum of the cells should be 36-37 mm.

The hive must be simple in design and have the exact (standard) dimensions of all parts, be comfortable in work, not heavy, adapted to transportation, and also easy to manufacture, inexpensive and at the same time durable.

Of great importance is the proper care for the hive – timely repairs, quality plaster and regular painting it. Under these conditions, the hive can serve 15-20 years.

Frame hive systems.

At present, there are many frame hive systems. Usually they are divided into two main groups, depending on the direction in which they can be expanded nests of bee colonies. Those hives, the volume of which can increase upwards by putting on their main body of superstructures, are called vertical, or risers.

If, however, the volume of the hive nests reaches 12-14 frames, it can further increase not upwards, but aside, by setting the same frames next to those previously delivered, then these hives are called horizontal, or sunbeds. Usually they accommodate 20-24, rarely 16-18 nest frames.

Vertical hives are of two types: a) on a single frame, when the frames in the housing and in the extension are of the same size, and b) in unequal in size frames. In the latter case, they have so-called nest frames and storehouses – smaller in height than nesting. Hives into a single frame have a number of advantages: all honeycomb frames can be used to build up bees, the frame of the nested body and the extension in them are interchangeable.

According to the shape of the framework, the hives can be divided into two main groups:

1) hives with a low-wide frame, that is, with a frame that has a width greater than the height; this is the most common type of hive;

2) hives with a narrow-high (“inverted”) frame, whose height is greater than the width. In addition, in some hives, the upper bars of the frames are closed, that is, they are joined closely, in others they do not close.

The size of the frames in the hives of different systems is also not the same.

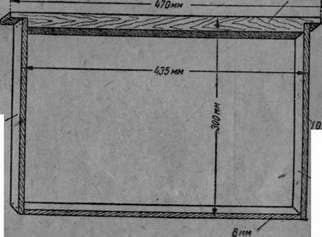

Fig. Standard frame with external dimensions 435 X 300 mm.

Fig. Standard frame with external dimensions 435 X 300 mm.

In Russia, the most common hives on the frame, the outer dimensions of which are as follows: length 435 mm and height 300 mm; taking into account the thickness of the upper bar – 20 mm, the bottom and side strips of 10 mm, the internal dimensions of this frame are: width, – 415 mm, height – 270 mm. The frame of the specified sizes and is called ordinary or standard.

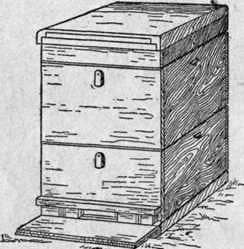

Double hulls.

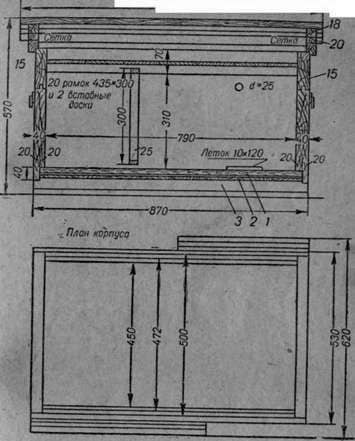

Of hives with extensions in our country is quite widespread 12-frame hive, consisting of a nest compartment (housing), which accommodates 12 nesting frames of 435X300 mm, and extension, or store.

In the extension there are half-frames, they are half the size of the nest frames. Half-frames are usually placed in a smaller amount, so that the gaps between them slightly increase. With this arrangement, the honeycombs of the magazine frames are considerably thickened by the bees by lengthening the (superstructure) of the cells. In such honeycombs honey bees can put more honey. In addition, they usually do not go to the uterus for egg laying, and this is sometimes very important when using a bribe.

Dimensions of the hull of such a hive inside: 450 X 450 X 340 mm. The dimensions of the store are 450 X 450 X 160 mm.

The disadvantage of a 12-frame hive with a superstructure on the frame is that its volume is too small to build up strong families in it for honey. Therefore, in many cases it is more advantageous to put two stores or a second building on the hull of such a hive, and then it can be used as a two-hull; in this case it accommodates 24 ordinary nest frames.

Two-hull beehives have a number of advantages over 12-frame beehives from the shops on the half-frames. In double-hull beehives, many more bees can be built up and strong families can be maintained; at the same time, each cell can be used much better and more fully.

Productivity of families of bees contained in double hulls with proper care is always higher than in 12-frame ones. Therefore, the content of bees in double hulls is becoming more and more widespread every year.

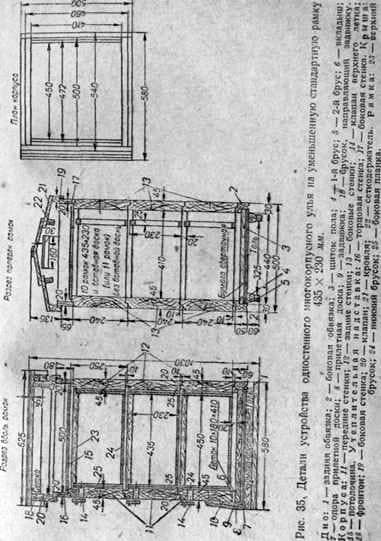

Hanging beehives also include multi-hull beehives. The frame in them is uniform, but reduced in height, the size, usually, 435 X 230 mm. In each case there are 10 such frames. Work in such hives is convenient and productive: work with individual frames is replaced by working with whole bodies. These hives consist of 3-4, and in conditions of a good food base and from a larger number of hulls.

Fig. Single-hull two-hull (general view).

Hive-loungers on 20-24 frames in the conditions of Ukraine have proved to be one of the best types of hives. Their volume is also sufficient for the development of strong families; You can have spare queens or uterus assistants next to the main family. Work in them is easier and more convenient than in double-hulls, in which removing the upper hulls (when working in the lower hulls) is associated with some inconvenience. However, the production experience of recent years shows that in Ukraine the productivity of families contained in two hulls is slightly higher than in 20-frame hives-sunbeds.

In general, the described hives-loungers on the 20-24 framework, double-hull and multi-hull are roughly equivalent and quite suitable for the conditions of Ukraine.

In addition, for the northern areas, a double-wall hive is also recommended for 14 standard frames and 12 storehouses, with double (front and rear) walls and single side walls.

The cut across the frames.

For the conditions of Ukraine, double-walled beehives are not suitable: they are heavy, uncomfortable for transportation, in summer, they create a large “stuffiness”, etc.

Cut along the frames

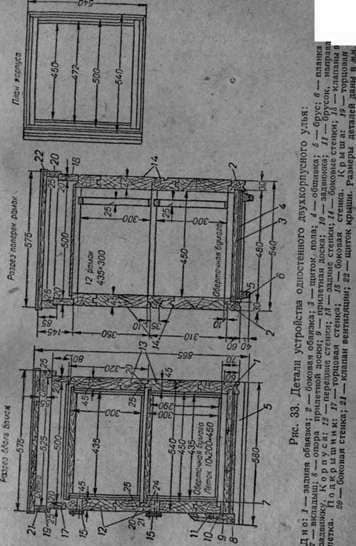

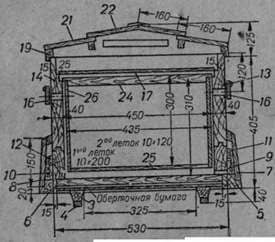

Fig. Details of the single-walled hive-lounger device for 20 standard frames (cross-section). Bottom: 1-floor flap; 2- covering; c – bottom of timber; 4 – lath rod; 5 – support of the first flight deck; 6 – support of the landing board of the 2-nd tap; 7 – landing board of the 1st staging; 10- gate of the 2nd tap; I-bar, directing the latch of the 1st tap; 12-bar, directing the latch of the 2-nd tap. Case: IS – front wall; 14 – rear wall; 15 – side wall; 16 – the valve of the upper tap; 17 – the ceiling. Roof a: I8 – gable; 19 – side wall; 20 – ventilation valve; 21 – the roof; 22 – net holder. Frame: 24 – the upper bar; 25 – the bottom bar; 2c – lateral lath.

Ukrainian beehive.

On the apiaries of Ukraine, other types of hives are common: Ukrainian, Levitsky and Vashchenko. Of these, the Ukrainian beehive deserves special attention. Distribution of hives Levitsky and Vashchenko decreases due to the fact that the standard sheets of artificial honeycomb, inserted in the hives for detuning honeycombs, do not fit in size to their frames, which creates great inconvenience when the frames are piled up.

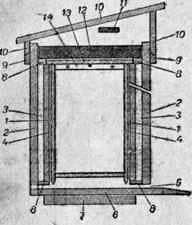

Ukrainian hive is made on 16-20 frames, equal to the standard frame, but turned to the side; The bottom is detachable, and therefore the beehive is convenient for cleaning, carrying and transporting. Two flaps in front: upper and lower, third – from behind or from the side, which makes it possible to make layers, have queen assistants and start wintering families with spare mats next to the main family. It is convenient for insulation, as the walls rise above the frame by 8-10 cm. The winter nest, consisting of 8-9 frames, is as if square. The spherical club of bees covers the whole width of the frame, and in winter it can only move upwards, which corresponds to the natural aspiration of the bees, since it is at the top that all the stocks of food are concentrated. Therefore, the hibernation in it goes well. The framework of the Ukrainian hive is often made close.

Fig. Insulated Ukrainian hive on 16-20 frames (cross section). 1 – internal walls of the hive – front and back; 2 – external walls – front and back; 3 – the space between the walls for the laying of the insulation material; 4 – the gap between the frames and walls of the hive; 5 – leaflet; 6 – the bottom of the hive; 7-cross bars of the floor; 8 – strips covering the warming material of the walls; 9 – bars on which the roof rests; 10 – the roof of the hive; 11 – the fan (with a lattice); 12-pillow for warming the nest; 13-frame; 14-upper frame bar.

This makes it easier for the bees to maintain the proper temperature in the nest and creates some conveniences for the beekeeper when preparing bee colonies for transportation. However, the use of closing frames has a significant drawback. Due to the absence of a “superframe space” (that is, the space between the upper frame bars and the ceiling) that could be used by bees in such hives, the ventilation of the nests deteriorates, and this, in turn, worsens the living and working conditions of bee families (especially strong ones) in time of the honey harvest, and also during the wintering period. To eliminate this disadvantage, beekeepers, where the hives with the interlocking frames are especially widespread, necessarily make the upper ones in such hives, except for the lower tapholes, the latter being considerably enlarged: in length 100-150 mm and in height – 35-50 mm , From the inside of the beehive, barring them with a metal net. In the spring and autumn, when the strong ventilation of the nests is superfluous, these upper flaps are tightly closed by bushings of the appropriate size.

In the carpentry workshop there should be 1-2 workbenches and a full set of tools in the required quantity: saws – transverse carpentry, perforating for transverse and longitudinal sawing of material with different width of cloths and different sizes of teeth, hacksaw, rewards; Sherchebels, planes with single blades and with blades provided with a chipbreaker, fugancers, selectors, sheet pile and fillet; chisels and chisels; Column with a set of feathers of different diameters; clamps, elbows, thicknesser; axes, hammers, mites, etc.

It is also necessary to have good accessories for sharpening and straightening tools: files, grinders, brusks and ditches.

At the workshop or nearby it should be a separate room (shed) for storing timber and folding ready-made hives and their parts.

For the production of hives, the most suitable tree is softwood: pine (not tarry), spruce, linden, poplar, willow, etc.

It is very important that the wood from which the hives are made is of high quality: straight, without cracks, wormholes, rot and with the smallest number of knots.

Wood for the production of hives must be dry: its moisture content should not exceed 15%. Of the raw wood, hives can not be made, as soon as cracks appear on them; in addition, parts of the hives will be severely wrinkled.

The boards become suitable (in terms of the degree of dryness) for the production of hives when they, after sawing, lie 2-3 years in a dry place, under a canopy or roof.

The drying process of the boards necessary for the production of hives can be greatly accelerated as follows.

At least 4-5 months before the hives are made, in spring and summer time, the boards must be cut into pieces (preforms) and laid on pads in stacks in attics of houses with iron roofs and, having opened the dormer windows, create a draft. Here, the blanks must be at least 3-4 months old. At the same time they will dry up considerably, but still their humidity will be much higher than 1.5%.

For the final drying of the blanks, they must be transferred to a warm dry room and placed on pendants (polatyah) near the heat source (Russian or heating furnace, etc.). Here they must lie for at least 20-30 days, after which they can be used for making hives and frames. As the space for drying the blanks in this room is freed, it must be filled with other blanks brought from the attic.

When making beehives, all parts of them must be made as accurately as possible: the deviation in the dimensions of the parts should not exceed 2 mm. Especially it is necessary to ensure that the inside dimensions of the hive housing and the external dimensions of the frames are most closely observed.

It should be pointed out that hives are made from local, non-deficient materials. Many beekeepers make good hives using straw. In this case, only the frame of the hive is made of wood, and its walls and bottom are made from hand-chopped straw, pressed and sewn in the form of straw mats. Often for the production of hulls such hives make a wooden machine, with which it is convenient to do this work. Also make the hives from the cattail.

Sometimes the hives are made of wood-straw. The hull and bottom of such a hive inside consists of boards 20 mm thick and externally furnished with a flat rye straw (without ears), the layer of which has a thickness of approximately 40 mm. In this case, the straw is held flat by slats that are close to it; Racks are nailed, which pass through the straw, fixing in the boards of the inside of the hive. The roof is made of a two-tier, thatched. These hives are not only inferior in quality to ordinary hives, made of good wood, but often exceed them. In spring, straw and straw hives are warmer than in wooden huts, and in summer – not so hot. These hives are durable, inexpensive and favorably distinguished from that of the straw, since they are almost never damaged by mice; if necessary, they can be easily disinfected.

Beekeepers in those areas where there are reeds among the local materials make good reed-plywood hives. The frame (frame) of such hives is made of wood.

The walls and the bottom on the inside of the hive are covered with plywood in one layer. On the outside, the walls of this hive are surrounded by several layers of neatly chopped reeds, attached to the frame. The bottom and the roof of the hive are also made. Sometimes a sheet of roofing is laid between the dictate and the reeds of the roof. Such a beehive – light, durable, cheap – fully meets the requirements for hives, and deserves wide circulation. Beekeepers make good, warm hives from the dictate, plating them with the wooden frames of the hives both from the inside and from the outside. The space between the inner and outer plywood skin is filled with waste fiber of flax or hemp. Outside, the hive is painted with a good oil paint.

In all cases of making hives from local materials, it is better to make them so that they are perfectly suitable for transport.

Hive