Wheelless platforms

Transporting the apiary to honey collection with minimal manual labor during loading and unloading of hives can be done using wheelless platform-selfloading trucks, transported by trucks or cars. The length and width of the mobile platform is determined based on the number of bee colonies, the body dimensions and the carrying capacity of a specific vehicle.

AA Type B

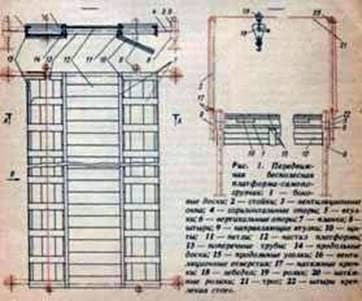

For the production of a platform transported by a lorry, two transverse pipes 13 with a diameter of approximately 80 mm and six longitudinal corners 15 are cut off, as shown in Fig. 1 (the corners can be replaced by two channel bars No. 10 or No. 12). Two corners are welded to the transverse pipes, four from the bottom, and four from the bottom, and along the line of the hives on the platform there are two guide bushings 9 with tension hooks 17 for securing the cable 21. The space between the upper and lower corners is sewn with boards.

In the transverse pipes insert horizontal supports 4 with welded to them bushings 5 so that they protrude beyond the dimensions of the body of the car. In the guide bushings 5, vertical supports 6 are mounted and fixed by the pins 8 in a position where the guide bushings 5 are located above the truck platform. Attached to the inner corners are longitudinal wooden bars 14, and boards of deck 12 are nailed to them, leaving the ventilation windows 3. In the two end boards 1, the ventilation holes 16 are cut out and closed with grids with latches. The two cavities formed by the boards are covered with shields that have been knocked into the dowel, which are hung by means of loops 11 to the inner corners.

Ventilation windows in the floor are covered with a metal mesh with small cells. On the decking in the places of installation of the hives, wooden slats 7 with a height of 20 mm are filled, forming the tapes and the sub-frame space, which replace the donja.

Under

When the handle of the winch rotates, the pillars rest against the car’s platform and raise the front of the platform with the hives. Lifting is carried out until the vertical supports are freed, after which they are removed, and the raised part of the platform with the hives is lowered onto the car platform. Then the stands with the winch and the cable are transferred and installed into the bushings on the opposite side of the platform, and the operation is repeated. When the loading is complete, the horizontal supports are turned by turning 90 њ around the axis, into the cross pipes, close the sides, and the racks are placed on the platform between the hives.

Upon arrival, the sides open the sides, put out horizontal supports for the dimensions of the body, put the posts, winch and cable lift one side of the mobile platform, install and fix the pins 8 vertical supports and lower the platform on them. Then carry the racks and lower the second side of the platform onto the supports. After unloading, the car leaves from under the apiary platform.

Before serving the bee colonies in the multi-hull beehives, the rails 2 are installed in the guide bushings 9. The rope is pulled through the rollers on the racks, the movable roller 19 is attached to the winch 18 and the gripper, the rope ends are fixed to the hooks 17 and the posts are fixed with pins 22. Having performed the necessary work in one row, the device is transferred to the second row of hives. In the case of deflection of the racks, they are provided with extensions or they place under the cable an additional portable stand with a groove for the cable.

On travel, the space between the platform and the vertical supports can be equipped for a nomadic booth or a warehouse for household and apiary supplies. At the same time in inclement weather, the platform with beehives is covered with a tarpaulin or a film.

With multi-body content of bees on the platform described, there is no need to produce pallets for hives.

For travel with a small amateur apiary, you can use a trailer to a car.

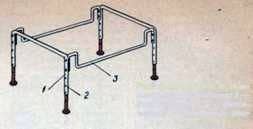

The basis of the platform for trailers with wheel niches inside the body is the curved tubular side rails 9 with a diameter of 42 mm, connected by fingers and pins 7 with an insertion tube 2 of the same diameter, and transverse tubular supports 6 with a diameter of 40-42 mm with handles 5.

On the square ends of the handles, the levers 4, made of a metal strip 5X 50 mm with rollers 3, forming the pulley blocks on both sides of the platform (one of them in Figure 2 is not shown) are put on the square ends of the handles. The rollers are connected in pairs by a rope 1. To the transverse tubular supports 6, the flooring 8 is fastened by brackets from the boards on which the hives are placed.

When loading platforms with hives, ropes pull the levers, which, turning the handles, lift the deck above the sides of the trailer. The ropes are fixed in this position and the trailer is pulled under the platform, after which, by loosening the tension of the ropes, the platform is lowered onto a light metal frame with pillars at the corners, pre-installed in the body. Next, remove the levers and side racks and place them under the frame on the trailer. There they also lay a tent, a portable box with a tool and other nomadic accessories. Unload the platform from the trailer in reverse order.

For a trailer with wheel niches located outside the body and a fully open tailgate, a platform consisting of lateral telescopic racks 1, latches 2 and bolts of transverse tubular supports 3 is bolted to the posts. A plank deck is attached to the supports (not shown in Figure 3) .

Fig. 3. Platform with telescopic racks: 1 – side racks; 2 – retainers; 3 – transverse supports.

The height of the platform is set so that the trailer with the open tailgate comes under it. Then, rolling a trailer under the platform, a jack lifts the side racks on one side, pull out the locks and lower the platform to the bottom of the body. The jack is brought under opposite struts and the operation is repeated. Remove the bolts securing the cross supports to the posts and lay the posts on the trailer. To unload the platform, the racks are fixed to the supports, they are raised one by one by a jack and fixed. The trailer is taken from under the platform with an open tailgate.

Wheelless platforms