Wine-growing plant for precious rubbish

What is planned to receive from the felling areas are trees aged from one hundred to one hundred and twenty years with a size of “waist” of a third of a meter or more. Transported business wood – at least 400 million cubic meters – with whips, that is, without branches and branches. At the cutting areas, well, we will consider one percent of the biological mass of felled trees. Even in this idealized situation, logging areas are carpeted with waste from a waste of 4 million cubic meters of wood. What kind of wood is it, the reader may object, – here and bark, and sawdust, and leaves, and needles. It is true, and technological chips – raw materials for production is available in this heap. And needles could be started with vitamin flour. But how to extract them separately from this carpet.

Do not choose the same on the chip, on the needle. You can still collect a heap from the ground, and sorting is a hopeless business. That’s rotting good in the felling areas, decaying money.

The scrap of waste was loaded into the drum and imparted to it a rotational speed such that only the leaves and other light and comparatively flat waste, for example, the thin bark, were pressed against its perforated surface by the action of centrifugal forces, and the rest – chips, twigs, coniferous shoots – turned inside. In the second stage, technological chips are extracted from the drum using a vacuum. And finally, branches, needles, small pieces of bark are blown out of the remaining pile with air jets. And since they have different shapes, volumetric weight and fly in different ways, they also land in different places. This is the principle of the new sorting device.

The laboratory installation with a drum of half a meter diameter and about two meters long sorted out 4 cubic meters of heap per hour. At the same time, if there were, say, 23.7 percent

Cutting by skating.

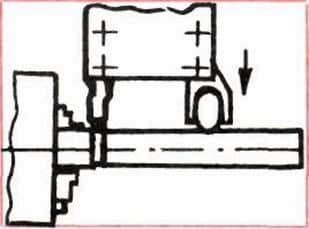

To divide into dimensional pieces, it is not necessary to cut the rod. Proceed as follows. In the clip of the lathe holder of an ordinary lathe, hold the holder with the rotating steel roller parallel to the tool. Set both tools so that the tip of the tool (latched at 60 њ) and the surface of the roller contacting the workpiece are equally spaced from the geometrical axis of the machine spindle. The cutter cuts a triangular groove in the workpiece – a voltage concentrator, and the roller presses on its console part. And although the depth of the groove does not exceed a tenth of a millimeter, the bar breaks off in a few seconds. In this way, it is possible to separate not only steel bars (relatively brittle), but also copper, and aluminum alloys, which are sufficiently plastic. The thing is that the rod under this method undergoes alternating bending.

If the workpiece rotates, say, at a speed of 600 rpm, then we can assume that the pressure roller in ten seconds will bend it fifty times in one direction and the same in the opposite direction. This load even plastic metal can not stand. 16-22 mm bars are broken off within ten to twenty seconds, depending on the plasticity of the material. The plane of the cut turns out to be grainy, but strictly perpendicular to the longitudinal axis of the rod, so that when the latter is turned on the lathe, it is necessary to take no more than a millimeter. At the usual cutting, at least three millimeters of metal, due to the width of the cutter, go away into the shavings.

Wine-growing plant for precious rubbish