Simple biogas plant

Over the past 30 years, biogas has significantly spread not only in countries with warm climates. Scientists estimated that organic waste of livestock in our country can give biogas in recalculation for conventional fuel – 25 million tons, and taking into account other types of organic waste – up to 40 million tons per year of conventional fuel. Such an amount of biofuel could completely solve the problem of gasification of villages.

Biological raw materials (biomass) – one of the most promising sources of energy. Biomass is manure from domestic animals, avian bee, feces, food residues, slops, debris, weed, stalk of plants, foliage, straw, wood waste, remains of food, meat, dairy industry, etc. Ie, practically all household waste in a rare and humid state, which have the ability to rot and wander, decomposing into “marsh” or “rattling” methane gas and high-quality fertilizer. If compost is prepared from manure for at least 6 months (30-40% of nitrogen and 50% of carbon is lost due to rain, wind and sun), then during methane fermentation practically all of the nitrogen remains, goes into its mineral form in the form of ammonium, is mineralized also phosphorus and potassium, and the carbon that is released,

From each wandering ton of manure (in dry matter) or other organic waste, you can get up to 0.5-0.6 tons of organo-mineral fertilizers. And for a very short period of time – 5-15 days instead of 6 months. During the biothermal process, all harmful pathogenic bacteria and even weed seeds are killed. The study showed that when growing potatoes, roaming dung affects crop yield better than normal. Yield increases by 20-30% compared with the use of compost, manufactured in the traditional way. Given the energy and agrochemical effect of biogas plants, their payback varies from 3 to 5 years. In addition, during the fermentation of biomass it is

Simple biogas plants

The principle of the biogas plant is extremely simple. The main condition for efficient fermentation with biogas release is heat without access to oxygen (anaerobic process). Pleasant conditions for fermentation come when the manure is heated to a temperature of 32 њ C by humidity 90-95%. When the temperature drops to 25 њ C, the gas yield will decrease to 65%. Methane fermentation is a bacterial process that takes place only under anaerobic conditions (without air access at a temperature of C-40 њ C – mesophilic, and at 52-56 њ C – thermophilic regime). This process does not require sterile conditions. It is not technologically difficult.

The fermentation time or the presence of raw materials in the reactor (fermentors) 5-10 days (thermophilic regime) and 10-15 days (mesophilic). It has been established that adding 30% of cellulose to pus increases biogas yield by 2-3 times. Biofuel from cow manure and bird’s afterburn contains 55-70% methane. The release of methane depends on the ratio of carbon and nitrogen in the process of anaerobic fermentation.

From pig manure for 15 days 57% of biogas is formed, and from cow-36%. Biogas is a mixture of gases: methane – 55-70%; carbon dioxide – 28-43%; hydrogen sulphide – 7%. A kilogram of manure gives 0.18 kg of methane, 0.32 kg of carbon dioxide, 0.2 kg of water and 0.3 kg of mule (humus). Depending on the content of carbon dioxide 1m3 of biogas equivalent to 0.6 kg of kerosene, 1.0-1.5 kg of coal, 2-3 kg of firewood. From a ton of fermenting manure, 300-400 m3 of biogas is formed.

Rational continuous fermentation process. The daily capacity of the bio-unit (reactor) should not exceed 10% of the volume of fermenting raw materials. The recommended duration of the fermentation process for pus cattle is 20 days, pigs – 10. The reactor is not only neutralizing, but also deodorizing waste. The specific smell and color of pus completely disappears. Biomass receives the smell of rye bread and a brown tint. The productivity of a biogas plant depends on the amount and composition of the organic mass incorporated in the reactor.

At a temperature of 33 њ C, the gas yield is 0.4-0.6 m3 per kilogram of dry matter introduced into the reactor. The average daily heat demand for a dwelling house (family with 5 people) equals 12110 kcal. To this value, 30% should be added to biomass heating in the reactor. So, the daily demand for gas for a residential house will be 2.9 m3. To produce such a volume of gas, 7 kg of dry organic matter per day, plus up to 90% of the liquid, is needed, which is entirely real for a developed personal household farm with a mixed set of animals (cow, heifer, goby, pig with litter, ewe with lambs, poultry).

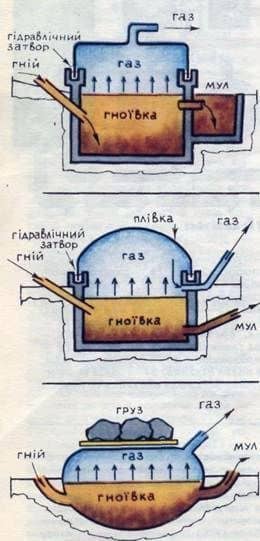

The simplest biogas plants are common in countries with a warm climate (in this case biomass does not need heating). They are an ordinary concrete pit for a crib where rare manure is thrown out through the tray, there are added slops from the kitchen, faeces, weeds, etc. After filling, the pit is covered with a floating tin cap or a bag of polyethylene film, from which the tube-gas pipeline leaves. As soon as the mass begins to wander, a gas is collected under the hood, which, through the gas pipeline, goes to a gas tank collector, the role of which can be performed by an ordinary camera. The pictures show the simplest biogas plant.

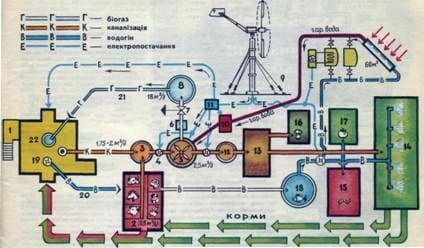

Utilization and energy block of rural manor with complex installation of biogas, solar system, wind turbine and waste processing for fertilizing beds.

Food

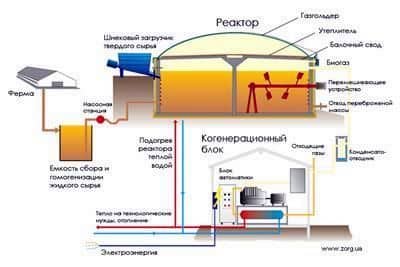

Technology system:

1 – an apartment house for a family with 4-5 people (daily outlet of drains 1.75-2 m3); 2 – cowshed for livestock (cow, heifer, goby, horse, sow with litter, sheep, poultry, daily yield of manure 0.5 m3); 3 – a collection tank of manure, domestic fecal water, slops and other wastes; 4 – pump-chopper NDC-F-100; 5 – insulated reactor with a stirrer and a continuous heat exchanger; 6 – the output of biogas and its purification from sulfur; 7 – the non-return valve; 8 – gasholder; 9 – wind generator in conjunction with the solar system; 10 – heat accumulator; 11 – electric drive; 12 – reservoir of roaming mass; 13 – pump and closed compost site; 14 – composting in soil and irrigation; 15 – worm for fattening of poultry and fish; 16 – champignons on compost; 17 – greenhouses, greenhouse, greenhouse on compost; 18 – ecological dome (fish pool under glass); 19 – artesian borehole; 20 – water supply to the shed, solar system and watering of the plot; 21 – gas supply line; 22 – gas boiler for heating and hot water.

The pit, covered with a polyethylene bag, combines both the reactor and the gas tank.

To the bag is not very swollen and to create pressure, a stone is applied to the film. A pressure gauge and a warning valve adjusted to a certain pressure are installed on the initial branch pipe. Otherwise, an explosion may occur. When the mass is fermenting, a crust forms on its surface, which interferes with the escape of the gas. It should be broken daily by mixing. It’s easier to do this by attaching steel forks to the hood. When they will rise upwards, squeezed out by gas, forks will destroy the crust.

Periodic loading and unloading of the reactor is inconvenient in everyday life. Therefore, reactors are produced continuously. This can be cylindrical, vertical or horizontal capacities without heating, deepened into the ground (only for southern regions). In the regions to the north, reactors with heating are needed. Of particular interest is the utilization – energy block (URB) using biogas and unconventional energy sources – wind, sun, heat of the earth. This is a completely closed self-contained system of life support for a peasant household or a family farm based on the utilization of industrial and domestic waste from the generation of gas, electricity and valuable fertilizer for the production of environmentally friendly food.

This system includes a system of irrigation farmstead (with farm) fodder field. The WEB scheme has this form (see diagram). From the cattle manure enters the reactor, further biomass falls into the centrifuge or on the vibrating screen, where the distribution of solid and rare fraction occurs. The condensed biomass is dried with the help of a solar system, they are also made during the spring plowing in the form of powder or dry briquettes (by the way, they can also be used as fuel – dung).

In the summer period of growth of fodder crops, a rare fraction is diluted with irrigation water and is pumped through the filter into the stationary collector of the sprinkler system laid along the feeding field. Through the tees to the manifold in different places connected mobile sprinkler unit. Fertilizing qualities of stray manure, diluted with irrigation water, higher than normal, as well as humus. With such intensive production of feed, the yield of fodder crops will increase by 120-150% compared to traditional cultivation. At the same time, the area of the forage wedge will decrease significantly by a factor of 1.5-2, which is very important in densely populated areas, for example, Donbass.

The recycling unit on a family farm can develop into additional production of by-products. In particular, it is possible to produce a worm for fattening broiler chickens and fish in an artificial pond – an ecological dome (combining a greenhouse with a swimming pool). On biomass, flies can be planted (the so-called fly technology for the production of fodder proteins), biofuel for greenhouses, greenhouses, etc. In short, the possibilities of using and searching in the field of wasteless technologies are unlimited, especially on the basis of those farms, farms, farms, where 25, 50, 100 and even more heads of large cattle abstain. So, there is a rather interesting development of the WEB farm for 100 cows.

Only one conclusion – the biogas plant can become an indispensable element of every peasant household or family farm. The construction of these installations – promising method for saving of fossil fuels, which solves both the problem of improving a country life. They will find their place in the garden societies.

Integrated use of biogas waste provide environmental protection by disinfection, deodorization, revitalization (inhibition similarity weed seeds), disinfection manure, improving sanitary-hygienic and welfare on the farm on the edge, leveling negative effect on animal waste soil, water and air.

Simple biogas plant