When framing frames and equipping them with wire, the side strips are often split, so many beekeepers pre-drill holes in them. I offer readers a simple and convenient machine of their own design.

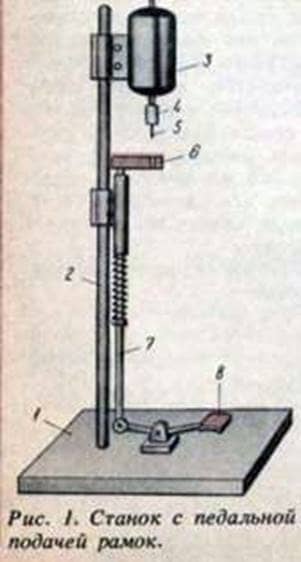

It consists of a massive base 1 and a supporting pipe 2. At the top of the pipe there is an engine 3.

A sleeve 4 with a short drill 5 with a diameter of 2 mm is firmly fitted onto the motor shaft. The drill and bushing are fixed with screws. Under the engine is a support table 6 with an area of 35X50 mm, on which the frame is vertically hung.

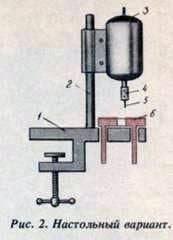

The frame for the drill is fed by the lever 7 with a pedal foot drive 8. It is possible to facilitate the manufacture of the machine by refusing the lever feed of the frames. In this case, the frame from the support table must be lifted to the drill by hand. The accuracy of the work and the performance in this case vary slightly. The same machine can be adapted to work at the table.

For preliminary marking of drilling points I use a template and a centracker.

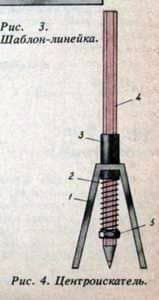

The template for the lateral marking of the side panels is a wooden ruler 25 mm wide with slots slightly more than half its width. Ruler I put on the side bar of the frame and put a mark through the slits with a pencil. Then with the help of the centro-scanner I make the longitudinal marking of the bar. At the intersection of the lines I get drilling points.

The center finder consists of a steel U-shaped bracket 1-1.5 mm thick, to the crosspiece of which is soldered a tube 3 for pencil 4. The soft pencil 2 is applied to the pencil from below. The latter rests against a M-8 5 nut screwed onto a pencil. The center-finder allows you to divide the bars, which differ from each other in width, exactly in half. Holes under the nailing markings are not required and are bored until the frames are framed. During the day, I mark out and drill holes in the 250-300 framework.

Advantage of this machine before the four-spindle, used for drilling frames, in the simplicity of its manufacture and small engine power. For satisfactory operation of the machine, 12-24 W is sufficient. A suitable DC motor is a DC motor from an automotive wiper or heater. In this case, the current source is a battery or a rectifier.

Отвар шиповника с медом. Вторая жизнь лампе.

Fixtures and fixtures