Treatment with oxalic acid

Reports on the use of oxalic acid vapors in varroatosis caused the response of beekeepers. They offer their devices and devices as evaporators. Many proposals deserve attention, and some are not without serious shortcomings.

The idea of processing bees in pairs of oxalic acid appeared long ago and was tempting with its simplicity and speed of execution. However, it took time to conduct a series of experiments and develop the safest way for the beekeeper and harmless for the family of bees and beekeeping products to feed the products of sublimation of the drug into the nest. The fact is that when oxalic acid is heated to 180 њ C, it melts and passes into a vapor state. Its vapors are nothing more than formic acid, which, having a strong volatility, irritates unprotected mucous membranes. This makes it necessary to observe the safety precautions in the treatment – work should be in the gas mask!

Oxalic acid is a dibasic acid, when heated it passes into a monobasic (formic) with the release of carbon dioxide.

As approved by the relevant regulations, for the treatment of the family with oxalic acid vapors, 2 g of the initial preparation is required, and the formic acid is 15-25 times more (30-50 ml). This difference can be explained by the fact that pairs of oxalic acid (actually already formic) are fed into the nest of bees in a hot state, as a result of which the impact dose acts on the varroa mite.

From the pharmacodynamic properties of some medications, it is known that with increased temperature during treatment, a more targeted effect on the pathological process (or on the pathogen) is observed. This was confirmed by the studies of A. N. Machnev (1989) when a cold fine-dispersion solution of formic acid was introduced into the nest of bees. At the same time, its antivariate efficacy was lower than in traditional methods – in vials, plastic bags

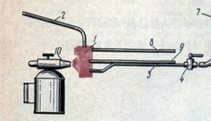

The amateur beekeeper as a device for sublimation of oxalic acid offers a quartz tube 1 with a diameter of 20-25 mm and a length of 450-500 mm.

Having fixed it horizontally at the level of the hive, it introduces into it a small rectangular boat 2 – a length of 35 mm, a width of 15 mm, a height of 10 mm, filled with oxalic acid in a dose of 2 g. After this, the tube is closed on both sides with tightly fitted conical rubber plugs 4 with metal tubules 5 mounted on them in the center, on which rubber hoses are put on. One hose connects to a “rubber frog” type rubber pump, and the end of the second one is inserted into the chute. Mounting the device, the quartz tube is preheated by the fire of the blowtorch, and then it pumps the formed acid vapors into a nest of bees. In our opinion, a disadvantage of the evaporator is that the vapors, when in contact with the cold walls of the rubber hose going to the tap, quickly crystallize and do not give the desired positive result.

Scheme of a quartz evaporator for processing bee families with oxalic acid vapor 1 – quartz tube; 2 – a metal boat; 3 – oxalic acid; 4 – rubber stopper; 5 – metal tube.

Fig. 1.

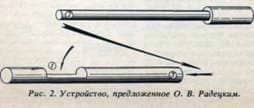

The chairman of the cooperative offers another simple device. A metal tube 3 with an internal diameter of 6 mm and a length of 30 cm at one end has a slot 1 into which 2 g of the preparation is filled with a measure. This part of the tube is injected into the chute, and from the opposite end it is inserted in the form of a ram, tightly fitted with a diameter metal rod 2, which is strongly heated by the lamp of a blowtorch. The rod has a handle for protection against burns. When moving it and contact with oxalic acid, the latter sublimes and its vapors enter the nest of bees. To process a single family take a few seconds.

The beekeeper greatly simplified his device. Instead of a tube, he uses a groove of roofing iron, on one end of which he pours acid powder, after which the device inserts into the tray. A very heated metal plate is advancing along the groove, which, upon contact with the preparation for 10 s, turns it into vapors entering the hive.

Both devices are simple to manufacture, but require special care when inserting a tube or groove into the tray, since the drug can wake up to the bottom of the hive. Also, the degree of heating of the rod and plate is uncontrolled. When they come in contact with the drug, the latter sublimes incompletely.

The disadvantage of these devices lies in the fact that acid vapors are fed into the nest of bees spontaneously, being distributed mainly in the lower part of the hive. All this undoubtedly reduces the merits of the method.

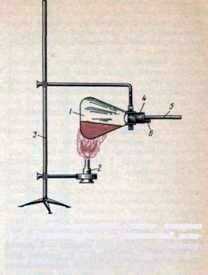

The acid evaporator described in the journal was somewhat modified by replacing the heating cylinder made of quartz glass with an ordinary heat-resistant laboratory flask, which can be easily purchased. The flask and gas torch for heating the acid are fixed on a tripod.

Fig. 3. Diagram of the device, whose author V. S.Taktakishvili: 1 – glass evaporator; 2 – gas burner; 3 – laboratory tripod; 4 – a wooden stopper; 5 – metal tube; 6 – the valve.

The neck of the flask is clogged with a wooden stopper with two round holes: one for the metal tube through which the acid vapors enter the hive’s flight, and the second is tightly fitted with the valve from the car chamber, the threaded part of which is connected to the pump for air pumping. When white acid vapors appear, the flask is thoroughly purged with air, and then the cork is removed and the dose of the preparation is again filled up to treat another family.

The disadvantage of this evaporator is that the flask is not cooled before it is filled with a new portion of the acid. This leads to a partial release through the neck of vapors, harmful to the beekeeper, the processing efficiency also decreases.

The beekeeper offers ordinary oxalic acid for the sublimation of oxalic acid, or, rather, a therapeutic smoke with an elongated flat tube. Preliminarily, the charcoal is kindled with red charcoal from solid wood (oak, birch), and then put on it a metal jar of such diameter that between the walls of the smoke and the jar there is a sufficient gap (1-1.5 cm) for the passage of air. 2 g of the drug is poured into the jar, the smoke is closed and, as soon as white pairs of oxalic acid appear, a spoutlet of smoke is introduced into the lower chute. A few rolls are injected into the hive by the pair and close both for 15 minutes. To protect the uterus from the action of a direct hot jet of acid vapors, it is preliminarily distilled from the bottom of the nest by two or three clubs of ordinary wood smoke.

To produce oxalic acid vapors, an electric soldering iron used in everyday life was adapted. The tip of the soldering iron is riveted so that a thin plate is produced from which a small spoon is made from the coining method, containing 2 g of oxalic acid powder; or to the tip of the soldering iron rivet the teaspoon without the handle.

In the prepared tip of the soldering iron poured the drug, injected into the lower chute and included in the electrical network. If there are hives with valves at the rear for the placement of mesh subframes, then acid vapors are fed through them (1-1.5 minutes). Using this method, he made a comparative analysis of the dynamics of scree of mites in bee families after different treatment methods, taking as thermal control. After checking the bee colonies (as instructed) twice, on October 5 and 14, with formic acid, folbek, acpin (neuron), phenothiazine, 2% aqueous solution of oxalic acid and its vapors, respectively, 160, 180, 200, 150, 140 and 15 mites. As can be seen, the difference in the effectiveness of antivariate treatment of bees by oxalic acid pairs is significant. The wintering of bees and the spring development of families pass without visible deviations.

Various electric evaporators are available, made from small glass containers, metal tubes of various diameters or ordinary smoke. The essence of the trick is to use electricity as a source of oxalic acid heating. The authors note that processing bees with oxalic acid pairs has several advantages over using a 2% solution of this preparation, since it is carried out later in autumn or early spring, when there is little or no brood in the families.

However, we note that such heaters are available to beekeepers, who have certain skills in working with electrical appliances. Such evaporators can be used only on electrified apiaries with the strictest observance of safety precautions – at least two people must work.

A noteworthy method is suggested by beekeepers of 20 g of oxalic acid, they are dissolved in 100 g of warm water, then 10 ml (per one family) of the solution obtained are passed through a syringe and passed through a copper hollow 1 heated on a primus or gas stove. The medical needle is hermetically sealed into the blank with the exit of the cannula to the outside. 2. The pairs formed at the contact with the hot walls of the chamber 5 through the nozzle 3 and the rubber hose 4 are gently pumped into the hive through the chute.

When checking the inner walls of the evaporator chamber, no acid crystal deposits were found on it. Treatment against varroatosis in this way is carried out at any time of the active season in the evening. This method is still not recommended for practical use, it can be tested on a small number of bee families. You can not use it during the period of honey collection.

Beekeepers are asked to describe the approved method of using oxalic acid by its sublimation method, as well as to give a drawing of the apparatus with the help of which it is possible to safely and efficiently process bee families.

According to the instruction for the use of oxalic acid in the varroatosis of bees, it is used in two ways: by finely dispersing the bees with a 2% solution or acid vapors obtained by its sublimation in a special device.

To prepare a 2% solution of oxalic acid, boiled water is used, cooled to 30 њ C (20 g are taken per liter). The solution is prepared before use. In order to compact bees on the framework of the hive, remove the full honey and pear honeycombs. Then, from the nest alternately remove the frames and spray the bees from both sides with any finely dispersed sprayer (“Rosinka”, “Shine”, garden sprayer, etc.). The aerosol torch is directed directly to insects from a distance of 35-40 cm at an angle of 45 њ, spending 10-12 ml of solution per frame (100-120 ml per family). Processing in multi-hulls starts from the lower shell.

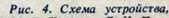

When processing bees with oxalic acid vapors, the top lettuce is closed in the hive, and 10-15 smoke smoke clouds are introduced into the bottom. Then, 2 grams of the drug are filled into the working chamber of device 1 (for every 10-12 frames occupied by bees) and heated by a blowtorch or other heater outlet tube 2 for 5-6 seconds, then injected into the lower tray and then 30- 40 s warm up the working chamber. After this briefly, for one second, the valve 4 is opened on the inlet tube 3 to supply oxygen or carbon dioxide from the cylinder at a pressure of 1.5 atm. In the absence of them, the supply of the acaricidal mixture from the working chamber of the device can be carried out by means of an automobile pump (4-5 complete rolls).

Before filling with a new dose of acid, the working chamber is briefly (1-2 seconds) cooled, lowering the bottom to the surface of cold water.

An important practical advice in the manufacture of the device is that the outlet tube 2 must necessarily be mounted on the cover of the working chamber. This achieves complete removal of acid vapors, they do not crystallize. The lid with the working chamber is conveniently connected by two links of the bicycle chain. From the inside of the lid, along its entire circumference, it is necessary to make a recess and fill with asbestos, which ensures tightness during operation.

This method is especially suitable for processing bees contained in pavilions, since it is not necessary to disassemble the nest and all work is carried out outside the pavilion. This protects the beekeeper from the harmful effects of acid fumes. If in the pavilion of the family are located in several tiers, the processing starts from the top. Depending on the degree of defeat, the family during the active season is treated up to five times. The first treatment is carried out in the spring after a mass flight of bees, if necessary, repeat it after 7-12 days.

After pumping out the honey, the treatment is renewed (1-2 times). This results in mass death of the tick in families, as a result of which the build-up of young bees going to winter will occur without the harmful effect of the parasite on their body. The ambient air temperature should not be lower than 16 њ C when treated with an aqueous solution and at least 10 њ C with acid vapors.

Thus, the processing of bees by oxalic acid pairs is quick to do, does not require much labor, is carried out without dismantling the nest in a practically fruitless autumn period and with a small amount of brood in the spring, which increases the antivariate efficacy. All this makes it possible to widely introduce this method in the practice of beekeeping both in public apiaries and in private households.

Treatment with oxalic acid