To make the wall of the hive body 450 mm high, you need to glue several boards into one shield. This operation I carry out with the help of the clamp I designed.

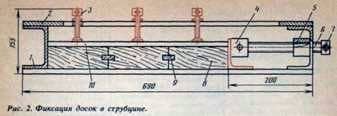

It consists of a frame 1 welded from two channels having a size of 100X300 mm and two corners 50X690 mm to which the plank of the pressing device 2 is welded. Two holes are drilled in the bar 2 where the clamps 3 are inserted. To fix the boards of the glued shield, a movable stop 4 fixed on screw 6, which, in turn, is attached to the frame by nut 5. The dimensions of the screw and nut are M 24X3. The stop is set in motion with the help of a wristwatch 7.

The sequence of work is as follows. Planks 8, designed for gluing, I prostrugivayu in one size in thickness. Then I process the side surfaces and using the 7X90 milling cutter I make a selection under the inserts 9. On the side surfaces I put the joinery adhesive and between the boards press the inserts. On top I put the bar 10 and lower the clamps 3 on it, and on the side fix the boards with the movable stop 4.

In a day I remove the prepared shield and cut it to the right size.

Due to the clamp construction, the shield is not deformed during the manufacturing process.

Переработка воска. Рамкам кормовая.

Fixtures and fixtures