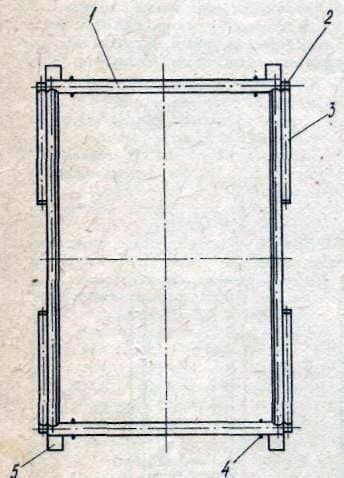

Fig. 1. Platform frame with composed racks (top view).

They transport apiaries to the massifs of honey plants for the fullest use of the spring supported and the main bribe, the growth of bee colonies for the winter, the increase in the yield of crops and perennial grasses. Kochevlya in the conditions of amateur beekeeping require significant expenditures of hard manual work, time, and therefore many masters can not afford. Timely, if you do not take out the apiary for pollination, honey will reduce, unkind agricultural products, including livestock.

Significantly reduced costs of manual work in the apiary, increasing its mobility, productivity while keeping families on mobile platforms. But their quantity, which is produced by the beekeeping plants, does not give much hope of meeting the demand in the near future and the platform price, mainly due to the chassis, is high, not affordable for everyone.

The proposed mobile platform without wheels behind the performance characteristics does not differ from a similar platform on the wheels – to transport each of them the right car. As for labor intensity and production cost, for a mobile platform without wheels they are much lower, less materials and expensive components are also wasted. The platform is easy to maintain and can be made at home from various wastes.

The dimensions of the mobile platform can be determined based on the number of bee colonies in the apiary, the prospects for their growth, and the size of the platform of the car that is supposed to be transported: ZIL-130, KAZ-608, UAZ-452, etc. The frame of the platform is welded from the pipes. To the longitudinal pipes along the entire length, one triangle is welded.

In the transverse pipes 1 of the frame, two inner tubes 2c are installed perpendicularly to the welded posts 3, extend the racks for the dimensions of the platform of the car and set them to the vertical position. Through the transverse outer and each inner tube, one hole is drilled, into which the metal pins 4 are inserted, which rigidly fasten the posts in an upright position. Four brackets 5 are welded to the frame.

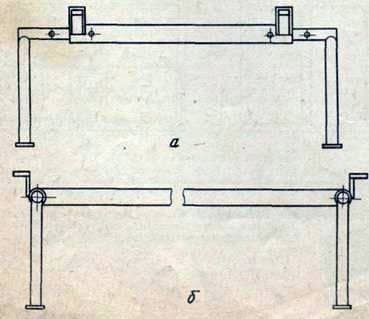

To transport the platform with bees to the honeycombs, open the rear and side boards of the car. Reverse the drive between the pillars under the platform. Between the front brackets of the frame put a section of the channel, and under it – the car jack and lift the platform to loosen the front posts, then take out the pins and alternately return the racks to the horizontal position. The inner tubes of the posts are turned to the outside of the stop and put on the platform of the car. Jack lower the frame to the dock with the platform of the body. Just take in and put the rear pillars. Over time, the sides are closed.

When arriving at the destination, unloading is carried out in the reverse order: open the sides, the platform with the hives is lifted behind; push, install, fix with pins the rear posts; install, fix the front, and drive out from under the car.

Fig. 2. Platform with separated racks: a) view in front; b) side view.

On a nomadic space between a platform and vertical racks equip under a nomadic box and a compound for household and beekeeping stuffing. In rainy weather the platform with beehives is covered with a tarpaulin.

A platform without wheels can be used for transportation of hay, straw, beet and crop of other crops from the garden remote from the manor, the field. In order not to hold the car for a considerable time under load and unloading, in the morning the platform is delivered and installed on the loading site. In the process of harvesting, the crop is poured into a container installed on a platform, raked and loaded with hay, straw, etc. The driver, who has freed himself from the main job, puts the platform on the car, transports to the destination and removes it from the car. To put the platform on a car or to take off, one person spends 10 minutes.

Пчелиная взятка. Клещ боится воды.

Useful tips for the amateur beekeeper