Home concrete mixer

It’s really cool. Himself personally used a similar device in the garden plot of a friend. For each batch of concrete (six buckets) took no more than a minute. And without calluses on his hands. However, in my opinion, in a concrete mixer, there is only one drawback: a loading hatch with a slide gate. No matter how hard you try, it can not be airtight. Cement “milk”, and this is the most valuable component of any mortar, will partially flow through the gaps in the damper. On a careful same zadraivanie loading hatch will take much more time than the actual batch.

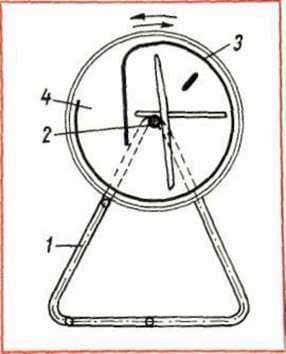

I suggest such a construction of a “court” concrete mixer. On the axis of the collet 2, mounted on frame 1, rigidly fixed shell 3, made in the form of a spiral Archimedes. Inside there are blades that enhance mixing when the shell 3 rotates. This shell is bent so that between its beginning and the end there is a window 4. With mixing of the material loaded into the shell, it is rotated clockwise and material from the window can not fall out, which occurs when the shell rotates counterclockwise when unloading the finished mixture. If the ends of the shell are made to protrude beyond the surface of the housing and put tires on them, the concrete mixer can be rolled from place to place as a trolley.

One of the cooperatives produced 100 such concrete mixers. Dacha they were ransomed instantly. However, someone “clever” decided that cooperatives should buy metal in tripod, and today none of our “court” concrete mixers does. But state-owned enterprises receive metal at wholesale prices. Why do not they tackle such consumer goods?

Motor scooter on plowing.

The original trailing implement to the scooter “Tula-200” designed and manufactured for plowing his garden Sverdlovich. This is a tillage mill

The four speed ranges of the gearbox of the motor scooter are practically enough to select the desired mode of tillage. The cutter thus not only plows, but also borrows the soil.

The plot of six hundred square meters is processed by the cutter in an hour. But the most interesting in the design is a very high efficiency and environmental benefits. The author has calculated that if a milling cutter operating on the proposed principle is not aggregated with a scooter but with an agricultural tractor, it can be made 30-40 meters wide, which is several times larger than the width of the capture of traditional agricultural implements of the same purpose.

And the wider the seizure, the fewer races on the field and more health on the ground. At one time asked the relevant authorities to conduct comparative tests, and in case of victory in the competition of his device over the serial “be kind enough to run it across the country.” Seven years ago no one had taken care of such trials. Maybe today?

Home concrete mixer