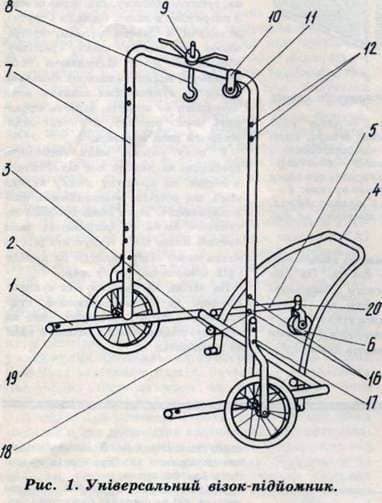

Fig. 1. Universal lift truck

A hand pallet truck is required in each household. Some design changes allow to significantly expand the possibilities of using this vehicle.

The welded frame 1 of the lift truck forms a technological space, where a load comes in which lies on the ground or stands on a stand. To the longitudinal pipes welded two semiaxes, on which the wheels are clad 2.

From the bottom to the transverse tube of the frame are welded two bushings 3 from the clamping screws, into which the handle 4 is inserted and fixed. If necessary, adjusting pipes 5 of the rear self-aligning wheels are inserted deep into the longitudinal tubes of the frame. Vertically to the frame, a welded load-lifting U-shaped riser 7 with a lifting screw hook 8, nut 9. A hole 10 is drilled near the left corner of the riser for the fixing bolts of the fixed block 11. On the vertical part of the riser there are two pairs of upper holes 12 where the drum 13 is attached with a handle 14, and an opening for the handle stop 15.

Fig. 2. Fastening the drum to the stand of the trolley

Likewise, the lower holes 16 and 17 are located. There are holes 18 for fixing the winch or drum for winding the pulley. In the hole 19 on the frame, a tent is set up, with which early bees or a bee are examined in an early spring. The ladder is installed in the hole 20 of the adjusting pipes.

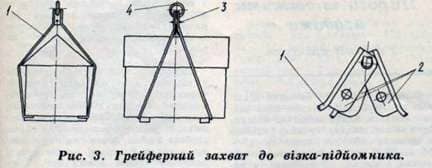

The clamshell gripper of the trolley-hoist consists of: hooks 1, metal plates 2, which form a lock. In the plates, two holes are drilled – the lower ones for fixing the load in the gripper with the help of pin 3 (they prevent spreading of the plates, and with them also hooks), the upper ones – under the ring 4 or the suspension bracket.

Depending on the specific conditions, the grip ring is worn directly on a load-lifting hook or suspended with a rope, chain, rope. Such a capture is mainly carried by heavy loads. To raise, for example, a hive, it is necessary to drive the trolley until it is in the technological space that is formed by the frame.

Fig. 3. Grapple gripper to the lift truck

Then it is necessary to take out the lock pin, to open tubular hooks, to lower, to lower or to cover with them a beehive. Then hoist or a pulley block to lift above the ground, transport it to a truck and again lift it above the platform. Lifting the handle of the trolley up the hive is put over the platform and falls on it.

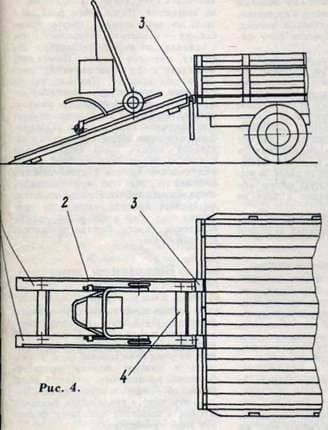

Loading of the hives is also carried out using a trolley and two wooden bars 1 with restrictive rails 2 on the sides. To the end of the bars fasten metal hooks 3. Between the bars join the slats 4. Before loading the bars one end is placed on the ground, and the hooks 3 are pinned against the open side of the car.

The beehive is fixed in a gripper, transported to a motor vehicle and rolled onto a platform by bars. When the trolley on the inclined plane moves upwards, the center of the weight of the load in the grip does not go beyond the extended rear wheels, and the load itself is in a horizontal position. In the right place, the hive is lowered onto the platform, the hooks are pulled out from under it, the grip is lifted up with the wrench and the trolley is taken down the inclined plane.

If the diameter of the wheels of the trolley is small and the frame touches the bars when leaving the platform of the car, then its longitudinal pipes arc bent upwards.

In the case when the load can be hooked with a conventional hook, then hang it with a rope to the cargo hook 8, lift the rear wheels by the handle, hook the load and lower the rear wheels to the ground. At the place of unloading, the wheels are lifted; When the cargo touches the ground, it is uncoupled.

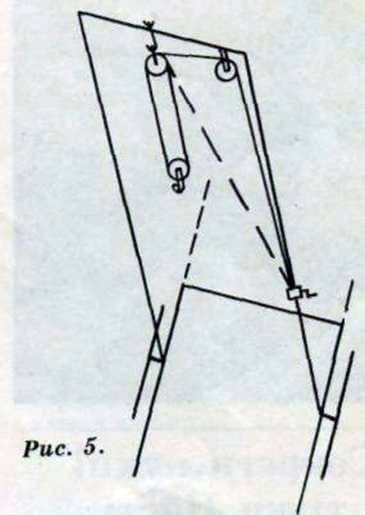

Heavy loads that need to be lifted onto vehicles, loaded and unloaded using a manual winch or pulley, fixed in accordance with the scheme.

Before weighing the goods on the cargo hook 8, hang a serial or homemade scales – bezmen. The string with the hook or hook is attached to the helm.

In order not to carry, do not manually move the hose to irrigate the garden or vegetable garden, drum 13 is attached to the holes of the trolley 16, the hose is wound on it, taken to the watering point, connected to the water supply and unrolled by moving the cart. Sometimes a trolley is attached to the cart. After finishing the irrigation, the hose is wound on a drum, transported to another site or to a shelter. Similarly, an extension cable is pulled over the section and it is also wound up.

It is much easier to pull from the deep borehole for repairs, preventive inspection of the pump, if during lifting the hose and cable from it are wound on a drum fixed in the boring hole 12 of the bogie.

The stepladder, tapered to the top, tilted to the riser, does not need additional support, does not require manual transfer, it is not necessary to lower the fruit, not filled up to the top with berries and fruit containers, when the ladders are moved to another place each time. It is enough for the collector to get off the ladder, to transport the cart, on which the stepladder is installed, and again to rise to the fruits and containers.

On a trolley of this design, you can arrange a swing for young children.

Виды пчелиных. Зимовка маток.

Fixtures and fixtures