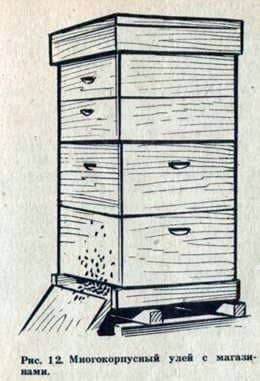

The best hive is one that resembles a hollow – the natural habitat of honey bees. This is just the case with the multi-hull vertical hive. In it, bees can live just as they have become accustomed to for many millions of years. It corresponds to their nature. He also answers the problems of modern practical beekeeping, both industrial and amateur.

A multi-hull beehive has been known for more than 120 years. During this time, its design improved and is now brought to perfection. In countries of highly developed industrial beekeeping – the USA, Canada, Australia, bees are mainly found in the hives of this system. Quite widely they are common in Europe. In our country they are also very popular among the advanced beekeepers of large farms and homestead apiaries.

A multi-hull is easily dismantled and collected. It consists of either identical bodies, usually 5-7, or from 2 3 shells for brood and 3-4 small branches – shops intended for honey. The hive set also includes nest and store frames, a bottom, a pilot insert, a ceiling, a roof, a stand.

The volume of the hive is unstable. It depends on the number of bees living in it and the amount of nectar brought. In the high season, for example, it can have 6 to 7 floors, and in the spring the family will have two.

Multi-corps apiary resembles a high-altitude city in summer. In each house, a skyscraper, 70-80 thousand residents, or even more. An apiary in 12 families is already a pchelograd with a million population. And after all, collective-farm and state farm apiaries and farms have 200-500 or even ten times more hives. What a huge army of bees works on collecting nectar and pollen, pollination of gardens, fields and meadows.

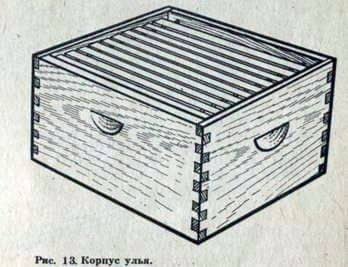

The hull is the main part of the hive. It’s a box without a bottom. Its internal dimensions are 450x375x240 mm. It includes 10 frames in the size of 435×230 mm. Wall thickness 35 mm. Recently, it began to decrease to 20-22 mm. Such thin-walled beehives do not worsen the life of bees, and it is easier to work with a hive.

In all the walls in the middle, 70 mm from the top are handles-shells, so that it would be more convenient to lift and carry the shells. The width of the shell is 60 mm, height 30 mm.

In the front wall under the sink is sometimes drilled a hole – a chute 25 mm in diameter. Make it and slit height of 8 mm, width 50-60 mm.

Front and back walls from the inside have cutouts – folds for hanging frames. Depth of folds 17 mm, width 11 mm. At this depth, a free space is formed above the frames, which allows you to place on the hive another extension or to lay the ceiling without any danger to the life of the bees that are at the top.

In the school workshop it is quite possible to manufacture cases. To avoid distortion, you must use the template, which clamped prepared parts. The destroyed shells are verified on a strictly horizontal slab, achieving a close contact at all points.

The store for honey has the same dimensions as the body, but its height is 155 mm. The frame for the store is also shorter – 435×145 mm. There are no holes in the shops. Stores are placed on the hives at the time of flowering of strong honey-plants.

And in the case, and the store extension comes in 10 frames. But the store usually puts them in 8. Honey combs, in which bees lengthen the cells, are more complete, the uterus almost never comes here to lay eggs. Long cells are uncomfortable for her.

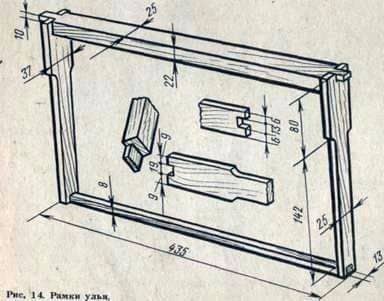

The frame of the hive consists of an upper bar with a thickness of 22, a width of 25 mm, side and bottom bars 8 mm thick. At the ends of the upper bar are made hangers, on which the frame is suspended. The side panels have permanent dividers. Their width in this part is 37 mm. Separators provide an accurate distance between the cells and the stability of the frames in the hive, which is very important when transporting bees.

In the side plates make 3 holes with a stylus or a hole punch for the wire. This three-row reinforcement firmly holds the honeycomb and protects it from breakages. The wire needs a thickness of 0.3-0.5 mm, tin-plated, stainless. In the shop frame, pull the wire in two rows.

The frames can be easily removed or, when necessary, rearranged in a hive from place to place.

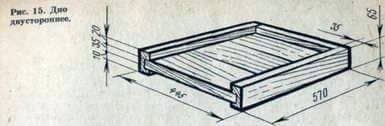

The bottom is a separate element of the hive, it is two-sided and one-sided. The two-sided bottom, or, otherwise, the reverse, is arranged so that if necessary, both sides can be used. A two-sided bottom consists of three bars and a floor. If the hive has a wall thickness of 35 mm, then the size of the side bars will be 570x65x35, and the rear side – 445X65x35 mm. In each of them, a longitudinal groove for a floor 35 and a depth of 10 mm is chosen so that a ledge in 20 is formed on one side of the floor and 10 mm on the other. The bars are fastened with wooden nails. In the grooves inserted a floor of sheeted boards.

Usually use the side of the bottom, which forms a large slit, if the bottom of the body. However, for small seeds, the bottom is turned. The bottom extends 50 mm beyond the body. This part serves for bees by a landing site.

The bottom is non-negotiable. To the floor on the sides and behind, nails are only strips in height 20, width 35 mm. They fasten the floor and form the sides, on which the body is put. For greater strength and durability, two blocks are beaten from below.

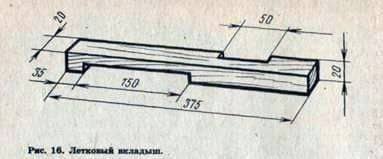

The flotation hole of the bottom is limited to a wooden liner – a bar section of 20×20 mm, the length of the entire lumen. It has two adjacent cutouts measuring 50 x 8 and 150 x 10 mm. In the cold season in the spring, bees fly through a smaller hole, with the strengthening of the family and warming, the liner turns into a large cutout, and with the beginning of a large honey collection it is completely removed.

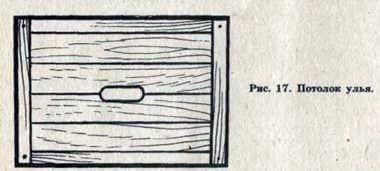

The ceiling of the hive has a size equal to the external size of the hull, – 520×445 mm. One side of it with a rim protruding by 5 mm. Lay the ceiling on the body with the side without the rim. In the middle of the ceiling there is a hole 40X100 mm for the ventilation of the nest, through it the bees get into the feeder when they are given food, a beeper is inserted into it – the honey bee removing bee. A thin cushion is placed on the ceiling to insulate the nest.

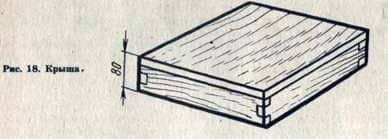

The roof is flat, covered with iron. It protects the hive from wetting during rains. The height of the roof is 80 mm. For enhanced ventilation, the nests in the roof in front and behind directly under the roof make a full-width cutout. The height of the gap is 10-15 mm. To prevent these holes from being covered with a warming cushion, 20×20 mm are beaten under the roof from the sides. The roof hangs over them. The holes do not bite.

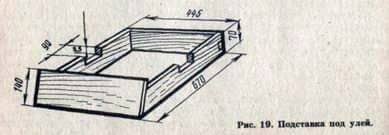

Multiple hulls are placed on solid supports. Do not use pegs in place of the stand, as they are. a multi-hull can not stand. In addition, they are very inconvenient in carrying out many important works.

There are many constructions of supports. The most common is a stand made to the size of the bottom. Its height is 70 mm. The sides of the front are bevelled at an angle of 45 њ. To them is a landing board, at the top, too, beveled so that the bottom of it is snugly seated.

In the sides of the stand there are notches with a size of 25 x 90 mm. They allow you to take a beehive by the bottom or stick a fastening tape to pack it for transportation.

All parts of the multi-hull must be closely adjacent to each other. After all, bees, like water, quickly seep through the cracks. When making hives in the workshop, therefore, it is necessary to observe exactly all dimensions, up to a millimeter. Standard parts are a prerequisite.

Работа в улье лежаке. Соевая мука для подкормки.

Hives, inventory