I bring to the readers’ attention a water wax-furnace of my own design.

It consists of an enamel tank 1 with a capacity of 20 liters, manufactured by the industry for household needs (height – 50, diameter – 27 cm), cover-press 2 and metal hook 6. As a cover, the press used a conventional pelmennitsu, which successfully approached the diameter of tank, so that the gap between its edge and the wall of the tank was no more than 1.5-2 mm. On the underside of the pelmennitsa fixed a net with a cell 3X3 mm with legs-stabilizers 3 of length 15-20 cm. The latter exclude the possibility of turning the cover-press during operation.

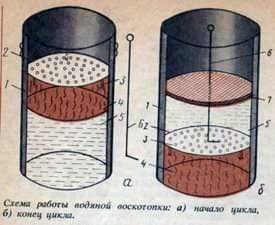

The tank is loaded by two thirds or three quarters of its volume with a crushed voskarysem 4, top put the lid-press 2 and pour it with soft (rain) water 5 so that the water level is 3-4 cm above the level of the lid. Then put the wax on the tile.

As it warms up, even before boiling (at a temperature of 63-65 њ C), the wax begins to melt and rises through the holes of the mesh in the cover-press upward, to the surface of the water, and the lid-press under its own weight gradually descends. Through one of the holes in the center of the cover-press inside the tank I enter the hook 6, which periodically (after 5-10 minutes) I mix the raw materials at different levels of the tank.

The resulting film of melted wax on the surface of the water creates a so-called “pressure cooker effect”, resulting in a warming temperature of 110 њ C or more, which reduces the time of waxing up to 30 minutes (from the beginning of boiling), promotes sterilization of the wax and its fuller exit.

After the end of the working cycle, I removed the wax-up from the plate. To cool the tank, I immerse it for 10-15 minutes in a barrel of cold water. Frozen and straggly wax disk (due to different coefficient of thermal expansion) is easily removed and starts a new working cycle. The yield of wax is 320-340 g.

Лесные пчелы. Органы пчелы.

Fixtures and fixtures