Wax raw materials in the apiary are processed in two ways: without boiling – in wax and with boiling – on voskopresse. The greatest yield of quality wax is obtained when pressing raw materials. The magazine published a lot of descriptions of the original high-performance designs of waxes, allowing you to combine the processes of digestion and pressing.

However, despite their dignity, not every beekeeper will dare to repeat these designs, since in addition to the scarce materials for their manufacture, it is necessary to have a metalwork qualification and involve the work of other specialists. I bring to the attention of beekeepers the construction of the wax-up, in which the processes of digestion and pressing are combined. And the pressing goes on continuously throughout the whole cycle. For its production, scarce materials and tools are not required. Everything is as simple and effective as possible.

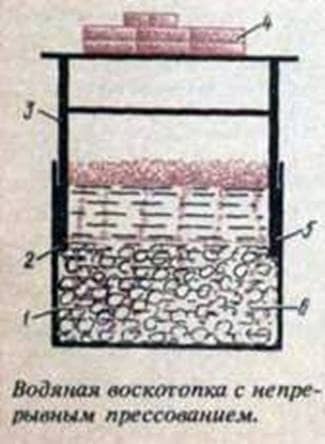

Made it from an aluminum pan for four buckets. On the inside diameter of the pot made a metal lattice, and from the irrigation hose – sealing ring, not allowing the boiled mass to break through the walls outward. In the tank 1 I put three buckets of land and 2.5 buckets of water. On the land 6 I put the sealing ring 2 and the grate S. I put the cargo area 3 on the grate, which is a wooden stool, and on it load 4 (six to eight silicate bricks). The land is compacted so that there is at least a small layer of water above the grate. I try to dissolve a strong fire. After the appearance of the flame wax begins to stand out after 5 minutes. After 10 minutes, the entire surface is covered with frozen wax flakes, and after 15-20 minutes all raw materials are boiled. The lattice occupies a stable position.

I remove the cargo, and the platform, due to excess steam pressure, begins to rise. Under the influence of steam and boiling water, the raw material is loosened, making it easier for the wax to exit through the grate.

Water boils just beneath it, remaining on the surface completely calm. 10 minutes after the removal of the cargo I put it again, on it a board and I hit it with a brick about twenty times. This results in large short-term pressures.

The first blows should not be strong, otherwise you can throw out some of the water. Then I remove the cargo and the cargo area and severely reduce the fire. From the moment the match is ignited and until the end of the waxing, about 45 minutes pass. During this time, the layer of water above the grate does not have time to heat up to the boiling point, and not all of the wax is melted. Then cover the pan with a lid.

As a result, the outflow of heat decreases and the remaining wax melts. When the pan cools down, I take out the wax circle. At the bottom there is a dense layer of Measure with a thickness of 2 to 4 cm, depending on the quality of the land. Merv I loosen the beekeeping chisel and put it to dry. Such raw materials are suitable only for extraction treatment. The grate is easy to make from the lid of the same pan. It is enough to cut it in the inner diameter and drill the holes. If there is no drill, you can take a nail and a hammer. Iron, zinc and copper can not be used to make the lattice. It is best to make it from wooden slats and a rare sacking.

Лежаки для пчел. Лесные пчелы.

Fixtures and fixtures