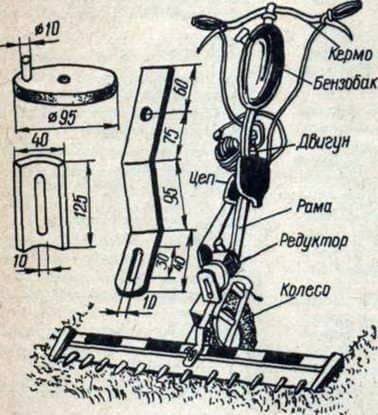

We are talking about a mechanical braid.

To produce it, some serial products needed from the bicycle – a D-6 engine with a capacity of one horsepower, a rudder, a chain drive, in addition, a wheel from a scooter, a piece of a water pipe with a diameter of C-35 mm for the frame, and a working organ will be needed.

The rotation from the engine through the reduction chain transmission (gear ratio 2.7) is transmitted to the gearbox (with gear ratio 1). On the initial shaft of the reducer, a disk with a finger is attached, which is installed with an offset relative to the center of rotation. The finger enters the hook with the lever, the plate of which has a slotted slot-groove. When the disk rotates, the finger moves the plate, converting the rotating motion into a reciprocating motion, which is transferred to the working member-knife by means of a plate.

All elements of the frame are connected by electric welding. The site for the reducer is made of sheet steel with a thickness of 3 mm. In the center of the site, holes are drilled for bolts, with which the clamps of the bearings of the wheel axle are fixed. The axis and the bearing are picked up by the wheel.

At the top of the frame, the steering wheel is attached to any bicycle, and a corner is attached to the bottom of the frame. It drills 12 holes with a diameter of 10 mm under the mounting bolts of the working element. A 890 mm long rail with 12 knives, 12 segment teeth and four guides are attached to the bolts.

Scaffold motto braids ready. At the fold of the frame mount the engine, on the site – reducer. The lever, made from steel with a thickness of 3 mm, is installed on the axis, with the finger of the disk must enter the groove of the plate. Mount the fuel tank, control knobs, adjust the chain tension and start the engine. The mechanical transmission must come into motion. If it works, then remove the extreme bolts on the corner and install the guides.

Now you can proceed to the scythe.

Пчелы в зиму корма. Рулет с грецкими орехами и медом.

Useful tips for the amateur beekeeper