With a simple device, it is possible to cut the pipe accurately at any angle to its longitudinal axis.

The pipeline approached the place where the trench turned to the side. The pipe is steel. After the trench, you will not bend it. The end of the pipeline is cut at the right angle, at the same angle, the next pipe is adjusted and welded.

Let us recall the course of descriptive geometry: the cross-section of the cylinder by a plane. Not every student managed to solve this problem the first time. A pipe with a diameter of, say, a meter is the same cylinder. Installers, with rare exceptions, universities, as they say, did not finish. But the eye is swept up. Draw a chalk along the perimeter of the pipe line – a minute affair. On it and cut off. Docked. Welded. However, a little bit did not guess. On the first docked pipe and unnoticed, that too sideways went. However, the longer the lash of the pipeline becomes, the more noticeable. Well, nothing: podnanuli, podnadavili, and then… catastrophe on the main product pipelines.

The installer knows or does not know the descriptive geometry; when marking, he mentally dissects the pipe with a plane at the right angle to its longitudinal axis and draws a line along the imaginary line of the section with a chalk.

In our adaptation, not an imaginary, but quite real plane acts, defined as any plane, by three points. This is a strong thread or a thin steel wire stretched over three rollers so that a triangle is obtained. What a plane, a hole from a donut, and not a plane, the reader can object. And we just need this hole. Thanks to it, the pipe to be detected is inside the triangle, as though perforating the plane defined by it. And yet there is no plane. There is only a triangular frame defining it. How do you transfer a non-existent section line to the pipe? We take the bar with a tight cord (some kind of a violin bow), we rub it with chalk, as it is done when piling lines on flat sheets, or we impregnate it with paint, and, drawing on any two sides of our triangle, we draw a “bow” surface of the pipe to be marked. The trace left by it is the line of section of the pipe by the plane at a given angle. At the same time, the accuracy of the markup is quite high.

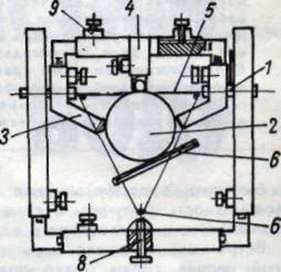

The frame can be rotated on the axes 1. It is mounted on the pipe to be placed 2 by means of supports 3 and the U-shaped support 4 located along the pipe 4. The supports end with balls, and therefore the frame easily moves along the pipe to the marking point. There, the frame is installed, making sure that the tensioned thread of one of the sides of the triangle 5 coincides with the initial marking point on the surface of the pipe. Then, the frame is rotated by a predetermined angle with respect to the longitudinal axis of the tube, and a marking element 6 is applied to the two sides of the triangle 5, as shown in the figure, and traverses the surface of the tube, moving along the filaments of the triangle stretched over the rollers 7. To tighten the thread of the triangle, screw 8 The eight locking screws 9 serve to fix the telescopic parts of the device when installing on pipes of different diameters.

The device is designed so that it can be quickly installed on the pipe, moved to the marking site, set one of the sides of the triangle to the starting point of the marking and tilt it relative to the longitudinal axis of the pipe at almost any angle. There is at our adaptation another good consumer quality. It is possible to mark not only pipes, but also constructions of box, triangular section and in general of any shape.

Thanks to the telescopic mounting elements, one device can be used to mark pipes in a wide range of diameters. We believe that the device can be used for the construction of main pipelines, installation of water pipes, process pipelines, pipelines for thermal and hydraulic power plants.

To make it is not difficult even in field conditions from auxiliary materials.

Замок на улей. Борная кислота и пчелы.

Useful tips for the amateur beekeeper