-the most highly productive

-The most economical

-the most convenient in operation

General characteristics of the hive

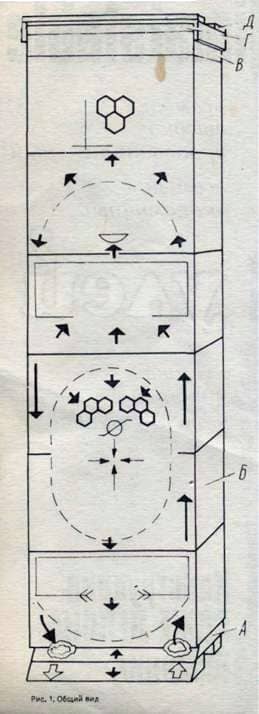

“Alpine” is a multi-hull hive, in contrast to similar traditional structures, it has one tap, no separation grid and no ventilation openings. Despite some external similarity with the four-hull, it is a fundamentally new design. An empty dry tree trunk (hollow) is taken for the model. Fresh air, enriched with oxygen, enters it from below through the ice, and, heated by the club of bees, rises upwards. Along the way, from the breath of the bees, it is saturated with a mixture of carbon dioxide, vapors, and metabolic products, and as a result, the moistened and weighted descends and leaves the hive. From the formation of condensation and moisture protects the feeder-ceiling. She is constantly on the hive and serves as an air cushion. The 30 mm roof-insulator above the ceiling reliably protects the bees from overheating or cooling.

At a time of large bribes, when the height of the hive reaches more than one and a half meters, the microclimate in it is supported by the build-up of hulls in accordance with the size of the bee club. The inventor has received the name “GLIMATSTABLE”, ie, more fully corresponds to the ideal natural conditions of existence and life of bees. Due to this, the alpine provides early intensive development, dry wintering, high productivity. It corresponds to the capabilities of the strongest beekeeping families in the most ideal years for honey harvest.

Contrast indicators of honey harvest from a new hive in comparison with traditional in the non-annual years. For example, in 1988 in the Carpathians, in the conditions of a single apiary, the yield of marketable honey from each of the 50 Dadan hives was 2 kg, and from Delonov’s hives – 22 kg. At the same time, three buildings were built from the artificial wax (that is, 24 frames) by the Alpians, and not one by the Dadans.

The highest-performance hive, according to its data, proved to be the most economical, the most convenient in manufacturing and operation. On it in comparison with others it is spent 2-3 times less than saw-timbers, at all the scarce tin wire is not necessary. The block arrangement allows 100 bee colonies to be placed on 0.4 hectares, that is, approximately 3-4 times more economical to use the area of the point. (Cases of bees and theft of honey are excluded). Shells are light. One together with full frames of honey weighs only 16 kg (11 kg of honey). The framework is also an undoubted advantage of the hive. They are well proportioned with the maximum capacity of bees to fill them with nectar, are strong enough that they do not break in the honeycombs at the highest rotor speed.

The hive is compact and allows optimal filling of the body capacity or the platform during transportation. In the autumn-winter period, he does not need to be insulated with cushions, mats and any rags – he winters well in an apiary under a single polyethylene bag.

The designer is happy with his brainchild. He is mostly one ruled with 1000 hives that are scattered by colonies in the Alps at a 120-kilometer distance. However, honey can not be pumped out properly. Does it in the winter.

In the photo: block arrangement of hives (equinox period). The second is on the left with the pollen attachment. In the center of each body is a recess for grasping with your fingers.

Technical characteristics of the components of the hive

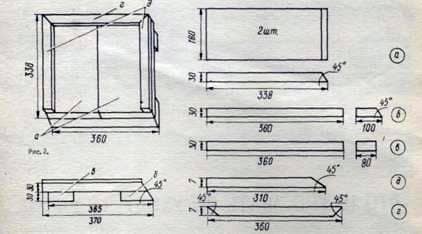

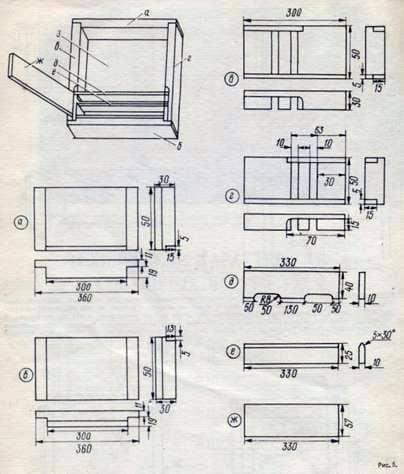

The bottom . It is made of pine impregnated with linseed oil, it is processed from the outside with carbonyl and covered with aluminum paint. Removable, every spring is replaced by a new one. The thickness of the bottom is 30 mm. The angle of inclination of the landing board is 45 њ. The height of the gap is 7, width – 300 mm. Fig. 2; a – the bottom; b – anterior foot; c – the back foot; d – plinth of the bottom, due to which the height of the tap is formed.

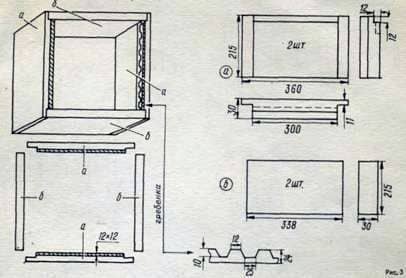

The body of the hive is made of 30-mm spruce or fir billets (two 360 x 230 mm and two 338 x 230 mm) impregnated with linseed oil. First of them, a four-wall frame with an external perimeter of 4×360 mm is knocked down, then the body is brought up to 215 mm in height. In the walls “a” there are ledges 12×12 mm for the installation of metal combs in them, excluding the displacement of the frames. The case is designed for 8 frames. Fig. 3: a – front and rear walls, b – side walls.

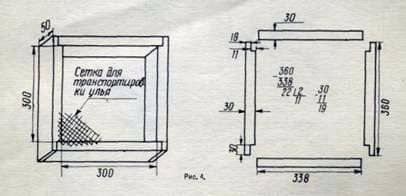

The cassette is universal. Serves for the formation of queen cells and the collection of uterine milk. Complete with a mesh used for transporting bees. The general appearance of the hive in the picture is without this cassette. Fig. 4; a, b – cassette walls.

Feeding trough. Its walls are made of fir and spruce. A small feeder cover that closes the two front compartments flush with the height of the walls – from a 5 mm fiberboard of 324×57 mm size, the bottom – from the same fiberboard 320×295 mm. The last dimension takes into account the three-sided 10mm allowance for the bottom entry, respectively, into the 5mm slots that are in the walls of the case, and keeps the 11mm passage into the feeder. The grooves under the bottom are sawed in depth by 10 mm with a 5 mm spacing from the bottom edge of the feeder casing to increase the collection of propolis. Propolis lining is stimulated by stripping plankochek at the place of its collection, i. e. on the reverse side of the bottom of the feeder. All parts of the feeder are impregnated with linseed oil, and from the inside they are additionally covered with white oil paint. Fig. 5: a – rear wall; b – front wall; c – left wall; r – right wall; d – septum with two passages for bees; e – the stance with which the bees eat the syrup; Ц – small cover; h – bottom of the trough.

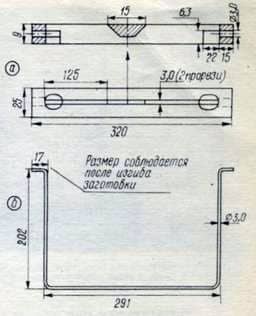

Frame with an artificial wax

Consists of a cherry or beech plank and mounted in a carrying black steel wire p 3 mm. The bar 320 x 2 x x 9 mm has in its flat part two slots 3 mm wide for filling the wax. The wire with a total size of 730 mm, curved in shape (see Figure 6, b), is flush with both ends flush into the end holes of the bar. Fig. 6: a – the bar of the frame; b – the wall of the frame.

The feeder cover is large – the ceiling of the hive. It consists of two sheets of solid furniture cardboard 360 x 360 mm 5 mm thick and pitted against the glue of a 20-millimeter sized insulated heater. From the alleged lower side is covered with white oil paint, with the opposite – linseed oil and aluminum pigment.

The clamping frame for fixing the ceiling of the hive in a fixed position consists of two 362 mm slats and two 382 mm wide 35 mm wide and 10 mm thick hard wood studded

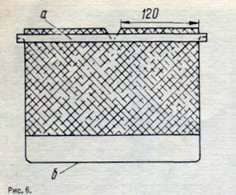

Base. Hives are installed block-by-4 (photo 1) on two parallel beams 1840 x 120 x 70 mm, which are firmly attached to two stable concrete racks (200 x 200 x 400 mm). The latter go deep into the ground so that the tapholes are about 15-20 cm above the ground. The interval between the hives on the uneven bars is 120 mm. 20 mm spacing on the edges of the bars are assigned to the fasteners for transport. The block of 4 hives has a common cover (1950 x 420 x 70 mm). In the flat part, it is a framework of 15-millimeter boards lined with a roofing sheet with a 70 mm opening for folding the trough.

The bars serving as a platform for the block, and the legs of the hives are treated with carbonyl.

As the same timber is used on the walls of the hulls, cassettes, feeders, 30 mm boards of 360 and 338 mm of the appropriate height, to provide a single internal perimeter of the hive 4 x 300 mm, when the nails are joined by 338 mm nails, there must be 11 mm steps of 360 mm billets. The entire hive (with all the hulls), in the collection form, is covered on the outside with aluminum pigment, except for a slatted board. It is recommended to paint it in colors that distinguish bees.

What you need to know after taking care of the hive.

The alpine is populated with swarms on piece wax, with layers if it is possible to use them from similar hives. But at first, many will have to colonize it by transferring the bee colon from the hives of other systems. This is done so. The case of the Delovnik, filled with an artificial wax, is set directly on the frame of the hive, from which they decided to transfer the family. Avoid significant heat losses can be, if previously adjusted, so that the opening of the hive beacon is commensurate with the nest of the Delonov Corps.

When the bees are pulled out of the wax in the extension casing, another one should be placed under it, also with an artificial wax. And as soon as both are built up and the eggs are laid in them, a third should be put between them, and then all together, taking off the obsolete structure from the hive, be placed on their own bottoms.

So there is a three-storey building only in case of development of a beehive – settling in it of a bee-family. In the following season, around the equinox, when the first honey-plants appear, two hulls left for wintering will also have to be built up by the third one, but it should already be with the frames of the finished sushi, and not an artificial honeycomb and put it not in the incision, but under the bottom of the wintering ones. This is done for the purpose of detaching the two shells from the brood above the tap and thereby inducing the uterus in a more favorable thermal regime to increase the laying of the eggs.

The fourth body is put between the two upper ones. This is done with a more stable bribe – flowering gardens. And as soon as the bees have built an artificial wax in this building, the fifth one is placed and again under the upper, that is, the fourth one. After the detachment of the artificial wax in the two upper buildings, a sixth body is placed between the fourth and third buildings, that water is also an anti-damage exercise, and an activity that limits the space for the operation of the uterus. Thus, even in the absence of a dividing grid in the hive, brood in it only 2-3 cases will be occupied, depending on the quality of the uterus.

In the hive of this design, it is always possible to use one housing for a nucleus. In this case, it is hardly worth abandoning the method of replacement of the uterus, which is used by the beekeeper. He does not even look for the old one, and immediately, having reduced the nest to one body and substituting the cassette for the lower casing, leads the productive family to the swarm state, which forces the mother to lay it down. Then the housing with the mother-cell is of course closed (top – ceiling, polyethylene and crimp frame, and bottom – bottom) is taken to a pedigree apiary, where young uterus mates with drones. After fertilization and egg laying, it is placed in the hive, in which it is necessary to replace the uterus, under the upper honey casing. There is, so-called, a quiet replacement of the uterus. Plus, the main family will be strengthened by the brood body before the main bribe. Note,

The production of honey in the hive is used from 1 to 5 corps, depending on the strength of the bribe. If the sixth is filled with honey, you should proceed with its pumping, after which the body with empty honeycombs is put. under the top, the one that is filled with the injection. If it (and all the usual ones) is placed at the very top, the bees will be forced to transfer the entire spray into it, ie, from the shell to the hull.

After the main bribe and shrinkage of the frames, the upper shells must be removed and deposited. The bees must remain in the 3 corps with a partially stocked sugar syrup or full, if you need to replace the honey. Thus, in the upper body there will be fodder reserves, on average – brood, in the lower, naturally, – perg.

Later in the autumn, when the brood emerges, the club will form in the middle body, under the dome of honey, located in the upper part of the hive, it is recommended to remove the lower one. Bees will spend the winter in the remaining two buildings with an open door and covered with just a polyethylene bag upstairs.

If the apiary is large, in the practice of caring for it instead of the traditional log of observations it is easier to coding hives with adhesive paper ribbons. Red is a selection, yellow is a piece wax, blue is a young womb, green is a sick uterus, blue and white is a replacement for the uterus, and so on.

And one more tip. Bracing the frame of the proposed design is a matter of minutes. A wax of this shape with the upper edge, which is cut out, is passed into the grooves of the bar so that the lower edge of it is at a 10-mm distance from the wire.

The released parts of it over the strip are fixed by rolling. You can grab a wax w e several places and to the side racks. The rest of the work is for bees.

Сахарный сироп пчелам на зиму. Весы в пчеловодстве.

Hives, inventory